NuSil Technology LLC, a global leader in silicone materials for the medical implants, aerospace, electronics and engineering markets, unveils R-2614, a transparent, flowable silicone encapsulant and potting material uniquely designed for easy processing and long-term reliability.

The robustness of R-2614 answers to market need for maximum protection of electronic systems, such as connectors, amplifiers, and even microfluidic devices, from the ambient environment. The new release of NuSil’s Electronics and Engineering business unit is also as versatile as it is effective due to its adjustable, temperature-controlled cure schedule and low viscosity.

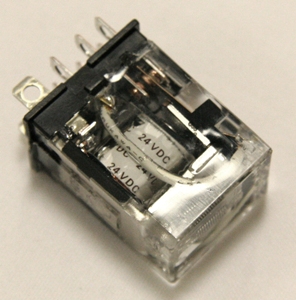

As a liquid silicone elastomer, R-2614 is flowable prior to cure, enabling it to easily conform to virtually any shape and to provide as thin or heavy a barrier as needed within the desired work time. Whatever the thickness of the material, the clarity of R-2614 facilitates assessment of electronic components, an assessment which includes measurement of the silicone’s own success in protecting the system from potentially inhibitive forces such as dust.

“R-2614 is highly valued for its flexibility and durability with regard to both processing and protection,” said Bob Umland, Marketing and Sales Director, Electronics and Engineering. “In addition to giving the silicone encapsulant a wide range of application suitability, these characteristics are part of NuSil’s efforts to respond to need with innovation for ever-greater silicone materials for ever-advancing electronic devices.”

R-2614 is a 10:1 mix ratio silicone that cures at room temperature within 24 hours and responds to heat with a faster cure time. It has been tested per UL 94, Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances.

For more information, please contact NuSil at +1 805-684-8780 or visit http://www.nusil.com/products/engineering/index.aspx.