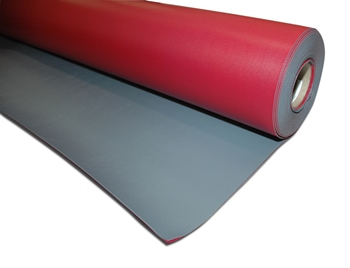

Airpad HTX is an uncured non-silicone rubber that can be made into caul sheets and flexible mandrels.

Airpad HTX has been formulated to provide enhanced performance in comparison to other rubber caul sheet materials.

Airpad HTX.

Airpad HTX.

Benefits:

-

Bonds aggressively to bondable release film, resulting in a longer lasting tooling.

-

Airpad HTX bonds to itself aggressively, making it easier to repair.

-

Heat aging studies show longer life in high temperature applications.

-

High Shore hardness for better definition.

-

Resistance to solvents, allowing the tool to be more durable.

-

AIRPAD HTX can be released using standard release agents. This should be tested by the customer using their release agents and prepreg before using Airpad HTX in any particular application.

ABOUT AIRTECH ADVANCED MATERIALS GROUP

Established in 1973, Airtech Advanced Materials Group consists of Airtech International Inc., Huntington Beach, California; Airtech Europe Sarl, Differdange, Luxembourg; Tygavac Advanced Materials Ltd., Rochdale, England; and Airtech Asia Ltd., Tianjin China, serves the aircraft-aerospace, printed circuit board, marine, wind power, automotive and recreational industries. Airtech is the largest privately owned manufacturer of vacuum bagging and tooling materials of its kind in the world. Airtech International Inc. is an ISO 9001:2008/AS9100 Rev C registered company.