Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, introduces thin film solderable coatings and face metallization, available on a wide variety of substrates.

Although silicon is the most frequently used substrate, the coatings can be applied to virtually all commonly used optical materials. The new thin film coating capabilities are enabled by DSI’s proprietary MicroDyn® sputtering deposition technology.

The face metallization and solderable coatings are typically used for hermetic sealing of sensitive packages. They can be combined with anti-reflective (AR), bandpass, or precision custom coatings from the ultraviolet (UV), out to the longwave infrared (LWIR) wavelengths. Applications include infrared detectors, cameras, focal plane arrays, and other sealed sensors and/or detectors.

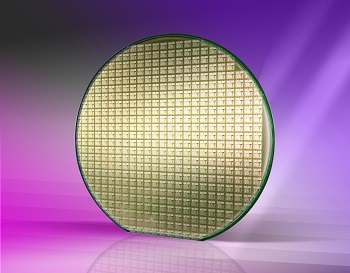

According to Dr. Michael Newell, director of sales and marketing at Deposition Sciences, Inc., “We are very excited about DSI’s new developments in solderable coatings and face metallization. Using our recently enhanced photolithography capabilities, these new coatings can be patterned at wafer scale, making them compatible with various wafer-level packaging operations that our customers currently employ.”

Deposition Sciences also offers custom coatings for one-of-a-kind specialty instruments, and can deliver high-volume wafer-scale coatings for various consumer applications. The company’s unique, ultra-durable, zero-shift optical coatings are MIL-Spec tested for humidity, salt fog, abrasion, temperature cycle, adhesion, solubility, and more.

For more information on DSI’s highly-durable, optical thin-film coatings, please visit www.depsci.com or call 866-433-7724.