Omniseal Solutions’ OmniSeal® spring-energized anti-blowout seal has been qualified as a static seal in rocket engine check valves for the aerospace industry.

Check valves are flow control devices that allow the flow of pressurized fluid (liquid or gas) in one direction only. In normal operations, check valves are in shut-off position where sealing is secured by static seals that are designed to withstand any blowout. Once the fluid pressure reaches or exceeds the rated threshold pressure, the valve opens and allows the fluid to transfer from a high pressure to low pressure side. Decrease in pressure to a level below the threshold pressure causes the valve to go back to its shut-off position. Check valves are also common in the oil and gas industry as well as in applications for pumps, chemical processing and fluid transfer.

In most cases, design engineers integrate check valves into their rocket engine designs. The role of seals in these vales is thus very critical in overall launch missions. Anti-blowout seals are used in check valves to retain pressurized fluid on the high pressure side while preventing blowout of the seal from the housing. Under high pressure as well as rapid change of pressure across the seal surface, retaining the seal in its housing is very challenging. Once the dynamic sealing surface of the hardware disengages from the sealing lip, there is a tendency of the seal to be blown away from the housing due to residual pressure around the seal. Normally seat seals, simple blocks of PTFE, are used in check valves but these seals’ performance are not consistent and over time, the seat seals experience permanent deformation resulting in leakage.

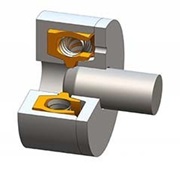

Omniseal Solutions’ anti-blowout seal, derived from their OmniSeal® 103A configuration, consists of a polymeric jacket with a spring-energizer. The jacket is made from a proprietary Fluoroloy® material while the spring can be made from materials including stainless steel and Elgiloy®. The spring can be heat treated and cleaned using special processes depending on the working condition of the check valve. An example of a general Omniseal Solutions’ anti-blowout seal in a rod sealing application is shown in the illustration at left (note: this illustration is different than the seal used in the actual check valve application, which is custom-designed). The seals in the check valve application operate from cryogenic temperature up to 575°F (302°C) and can withstand pressure up to 6,000 psi (414 bar).

The purpose of the OmniSeal® anti-blowout seal used in the check valve of the rocket engine is to seal pressurized gas and liquefied gas from temperatures below -300°F (-184°C) up to 122°F (50°C). The seal is proofed for pressure close to 3,000 psi (207 bar). The Fluoroloy® jacket material provides excellent wear resistance, anti-deformation, low coefficient of friction and very cold temperature capabilities. The OmniSeal® anti-blowout seal is designed to operate for hundreds of cycles without any leakage.

The OmniSeal® product line is available in multiple designs such as 103A, APS, Spring Ring II, 400A, RP II and RACO™ 1100A and are also offered in various custom designs. These designs include seal jackets in various Fluoroloy® materials and springs in various configurations. Omniseal Solutions’ sealing solutions have been used in launch vehicles such as the Atlas V rocket engine (which launched the Mars Rover Curiosity into space), Delta IV Heavy rocket and Falcon 9 rocket. Their solutions have also been used in other industries (oil and gas, automotive, life sciences, electronics and industrial) and in applications such as environmentally-friendly industrial dyeing process equipment, chemical injection pumps, the world’s first subsea gas compression station and chemical analyzers.

Please visit www.seals.saint-gobain.com for more information on spring-energized seals.