Market leaders in temperature controlled microscopy, Linkam Scientific Instruments, report on the use of their temperature controlled tensile stage at various Chinese laboratories for the research into biodegradable plastics.

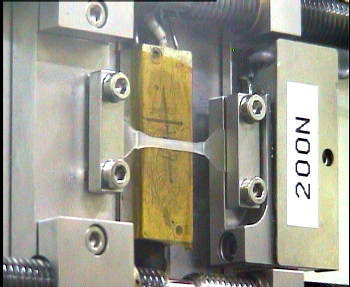

Polymer sample mounted in the Linkam TST350 tensile stage in use in Beijing.

Polymer sample mounted in the Linkam TST350 tensile stage in use in Beijing.

Global demand for environmentally friendly materials has increased drastically over the last few years making it a multi-billion pound industry. This in turn has driven the demand for the production and research into biodegradable plastics such as poly(butylene succinate), PBS. Teams from Beijing National Laboratory, Beijing Key Laboratory of Clothing Materials and Tianjin University in China have been looking into the structural characteristics of these plastics to see how they are affected by tensile forces.

PBS, is a thermoplastic polymer which has very similar properties to polypropylene but the most important difference is that PBS is biodegradable. Due to the fact that PBS naturally decomposes into carbon dioxide and water, it is much more of an environmentally friendly alternative to other common plastics. The array of applications and products in which PBS could potentially be used seems endless. It has already been earmarked as a potential biodegradable drug delivery capsule or as a replacement for polypropylene disposable cutlery, but so far, its biggest use is in the field of food packaging as an eco-smart alternative to the hazardous wrapping that is currently used on most foodstuffs.

As always, with the growing popularity and necessity of such products, a lot of behind-the-scenes research needs to be carried out in order to ensure that the materials are fit for purpose. The teams in China have been using a Linkam TST350 tensile stage to look at the properties of these materials. In particular, the stage has been used to observe the recoverability of structural parameters once a force had been applied to it.

The researchers were interested to see how the alternatively packed crystalline and amorphous layers of the semi-crystalline polymer behave during the deformation of the plastic caused by stretching it. The stage was used in conjunction with an X-Ray synchrotron to observe the polymer when subjected to stretching experiments whilst accurately controlling the temperature of the sample at various temperatures between 20 °C and 200 °C.

The team found that the equipment was “…small and easy to set up, which allowed us to use it in combination with an optical microscope or synchrotron”. They also added that “The displacement control was surprisingly good” and that the TST350 was the only example of a tensile hot-stage that they have ever come across.

The importance of understanding the processes that occur in the deformation of these materials is vital in the search for a perfect biodegradable material. The research being carried out on such materials will hopefully help us become less and less reliant on the use of everyday which are taking a large toll on the already stretched environment.

To see the full paper on this application, please visit www.linkam.co.uk/application-notes and learn about the broad range of applications in the field of temperature-controlled microscopy