Jun 2 2014

Researchers at the UPM have proposed a mathematical model to minimize energy consumption cost, which is associated to the production process adjusted to the time-based electricity rates.

A research conducted by the Projects and Quality group of Universidad Politécnica de Madrid (UPM) suggests advantages of the smart analysis in energy consumptions of discontinuous production processes, all in terms of minimizing production costs. This research opens the door to improvements in the sequencing techniques and machine scale work assignment. All this is translated in significant saving costs for these types of processes

Besides, this research has a positive environmental impact thanks to energy consumption savings during peak hours. All this would reduce power generators areas CO2.

Today, the planning systems of production tasks in work centres take into account the productive output of each team or of a group of teams when assigning a planning system. These systems tend to be more complex in order to ensure that all work tasks are completed before the deadline. They are also complex because of the team management configuration and the required time for it. This complexity is based on facts that have been traditionally considered real. For example, the fact that energy rate is fixed and has a manipulated price. The effect of this conception is that many companies are not aware of the detailed consumption of their teams at local level and in real time. Some companies only know and manage the joint energy cost and they study on how to adjust rate, the contracted power level and other global measures that can be effective but they might not always be the best decisions from the savings point of view.

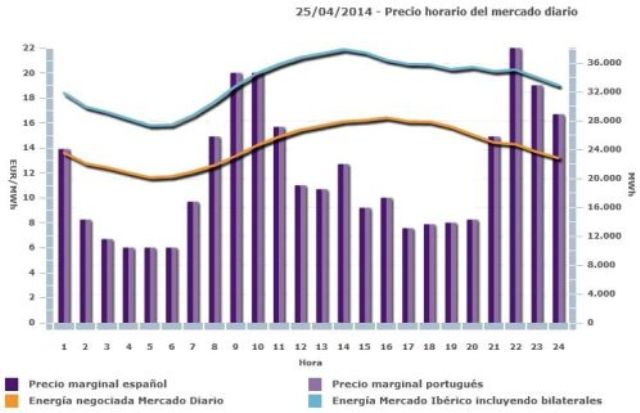

Nowadays, these hypotheses are considered less certain and the energy cost is not only more transparent, but also it can be estimated in hours (see the attached figure). Besides, the job market has changed and has introduced production flexibility. All this facilitates huge opportunities to reconfigure the tasking systems.

In addition, it is required to incorporate the Internet of Things (IoT) that allows monitoring the states of real consumption of diverse productive components and to integrate this information in the computer systems of the company. Thanks to these systems, we have improved the information for making better decisions. This way, the developed algorithm facilitates the paradigm in a way that a team can also conduct the local optimization, which has a tendency of minimizing the energy costs associated to production.

This project was conducted within the framework of an Erasmus Mundus Phd Programme.

SHROUF, F; ORDIERES-MERE, J; GARCÍA-SÁNCHEZ, A; ORTEGA-MIER, M. “Optimizing the production scheduling of a single machine to minimize total energy consumption costs”. Journal of Cleaner Production 67: 197-207 DOI 10.1016/j.jclepro.2013.12.024. March 2014.