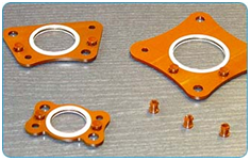

Omniseal Solutions OmniGasket™ sealing solution is being utilized in the Aerospace market as a flanged sealing component on aircraft wing slats and their deicing telescopic duct system. Retained in a gasket, this sealing solution is machined from a Meldin® 7001 polyimide plate with a static OmniSeal® seal installed inside, and is mounted at the interface between the telescopic duct and the wing leading edge.

When flying at high altitudes in subzero temperatures, ice forms on the wing of aircraft and a deicing protection system destabilizes the ice using hot air coming from the engine, thus allowing the slipstream to dislodge it and remove it from the wing. The OmniGasket™ component is currently installed on the Dassault Falcon 7X (a large-cabin, long range business jet) and being tested for use on a new mid-size jet.

Because the product is composed of two of Omniseal Solutions’ high-performance product lines (Meldin® 7001 thermoset polyimide materials and OmniSeal® spring-energized seals), it is capable of handling extreme service conditions and ideal for the Aerospace market. Recent research and development from the Omniseal Solutions manufacturing team has led to a change in the OmniSeal® seal shape from round to oval and optimizing the limited space. Within the same plate size, the oval shape supports a larger surface area, which increases air flow intake.

Other advantages of the OmniGasket™ solution include:

- One single component to replace two parts (providing the benefits of an insulating component as well as a sealing solution).

- Light weight material provided by a polymer solution compared to traditional metal plates in use.

- Mechanical properties and structural integrity at elevated temperature (up to 270°C) are very good, allowing an easy transition from metal.

- Machining cost of grooves is reduced because the component is installed between two flanges on plain surfaces.

- Ease of installation, i.e., installation plugs are also provided and made completely of Meldin® 7001 material, which is the same material as the plate ensuring inclusive thermal insulation.

- Excellent leakage capability, provided by the OmniSeal® element.

Meldin® 7001 material was specifically selected for the application due to:

- Excellent thermal insulative properties.

- Maintaining mechanical properties at elevated temperature.

- Capability of working well at cycling temperature (-55°C up to 270°C).

- Low thermal conductivity.

- Excellent ductility that is extremely important to ensure long life to the components.

- Low thermal expansion, being close to Aluminum counter surfaces.

The Meldin® and OmniSeal® product lines also work as separate elements and have been used for different applications in the Aerospace market, specifically in working conditions where high temperature or extreme pressure are needed. Some applications include jet engines, auxiliary power units, landing gear, gearboxes and flight controls.