Advancements in medical implants have often looked to material science for more robust solutions. Now a team from Louisiana Tech University have developed a novel technique for creating custom medical implants using 3D printers.

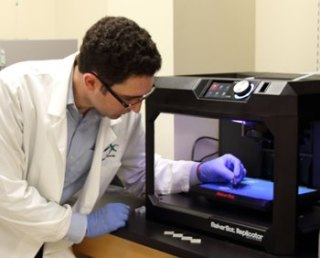

Jeffery Weisman, a doctoral student in Louisiana Tech University’s biomedical engineering program, uses a consumer-grade 3D printer and materials to create custom medical implant ‘beads’ that contain antibiotic and drug delivery properties.

Jeffery Weisman, a doctoral student in Louisiana Tech University’s biomedical engineering program, uses a consumer-grade 3D printer and materials to create custom medical implant ‘beads’ that contain antibiotic and drug delivery properties.

These implants can be loaded with medicinal compounds or antibiotics to enable targeted drug delivery.

The researchers belonging to the Nanosystems Engineering and Biomedical Engineering programs of the University worked together to fabricate filament extruders, which are capable of creating 3D printing filaments of medical quality.

Jeffery Weisman, doctoral student in Dr David K Mills lab, and Connor Nicholson, a guest researcher from Dr Chester Wilson’s lab, worked together to develop this novel technology with Dr Mills. This team also worked with the company Extrusionbot of Phoenix, Arizona, who helped with essential material support all through the testing process.

The custom 3D filaments designed by the research team are made from bioplastics and need not be removed by surgeons as they are reabsorbed into the body.

The 3D printing process at Louisiana Tech enables the fabrication of partly hollow beads, which allow more efficient drug delivery and a larger surface area. These 3D-printed antibiotic beads offer targeted treatment preventing large toxic drug dosages which may damage the person’s kidneys and liver.

Mills explains that presently there is a need for commercial-scale facilities to embed additives in plastic particularly to make sure that it is dispersed uniformly. However, this innovative method allows dispersing the additives at a table-top scale so that the additives are customized to the preferred levels.

One of the greatest benefits of this technology is that it can be done using any consumer printer and can be used anywhere in the world.

Jeffery Weisman, doctoral student at Louisiana Tech University

The team said the environment at Louisiana Tech played a large role in this project making the progress it has, in a relatively short period of time.

References