Image Credit: Alpha Galileo

Researchers from NIMS have created a highly efficient technique to develop friction materials with a specific frictional property.

A technique that can freely control a material’s friction coefficient is crucial to develop novel materials. This innovative technique promotes the development of materials with a friction coefficient suited to the specific application, such as high-friction materials for high-performance brakes and low-friction materials for lowering energy loss.

The technology of applying an existing structural material to control friction requires creating several samples with different crystal preferred orientations by modifying the coating conditions, and assessing their frictional property and crystal preferred orientation. This is a time-intensive process, thus lengthening the development process.

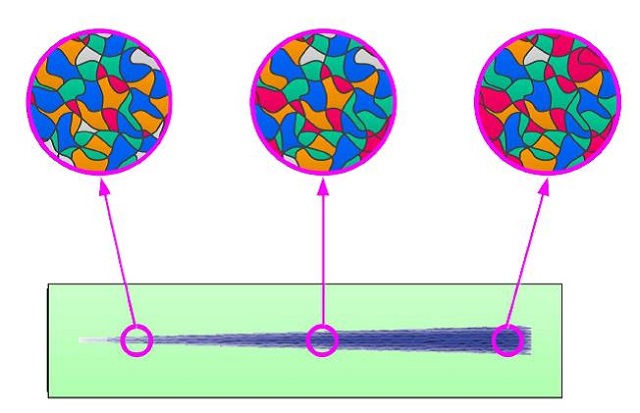

Conversely, the research group headed by Dr. Masahiro Goto of NIMS proposed a combinatorial tribological technique to develop friction materials by controlling crystal preferred orientation. The combinatorial technology allows for development of highly efficient materials that require only one trial experiment instead of performing experiments many times.

The NIMS technique enables acquiring information about the crystal preferred orientation as well as crystal structure to obtain the desired friction coefficient within a short span of time. In addition, the surface layer of a material’s crystal preferred orientation can be changed to a specific orientation by simply applying friction and modifying the sliding conditions.

Furthermore, the researchers were able to explain the correlation between the crystal preferred orientation and friction coefficient by conducting only one analysis. The research group also measured the friction coefficient of a point relative to the crystal preferred orientation.

This combinatorial technology holds potential to play a key role in friction materials research in the future. The study results have been featured in Tribology Letters.

References