Kobe Steel, Ltd.’s U.S. joint venture, Kobe Aluminum Automotive Products, LLC (or KAAP), has increased its production capacity of aluminum forged products for automotive suspension systems by 50 percent.

Kobe Steel, Ltd.’s U.S. joint venture, Kobe Aluminum Automotive Products, LLC (or KAAP), has increased its production capacity of aluminum forged products for automotive suspension systems by 50 percent.

KAAP's new forging presses

KAAP's new forging presses

Based in Bowling Green, Kentucky, USA, KAAP began construction of a $66-million expansion of its manufacturing facility in spring 2013. Construction was completed earlier this month and the new facility has gone into mass production. KAAP’s production capacity of 280,000 pieces per month has increased to 420,000 pieces per month.

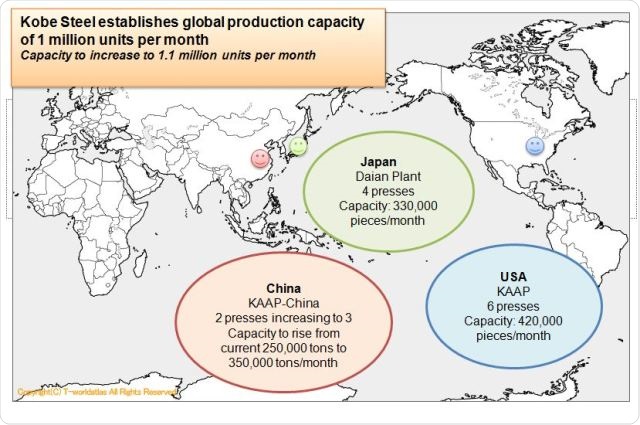

This expansion, together with Kobe Steel’s other manufacturing locations in Japan and China, gives the Kobe Steel Group a combined production capacity of 1 million pieces per month of aluminum forged suspension parts.

Car production in the United States, the world’s second largest market, grew in 2013 to over 16 million units. In 2020, car production is anticipated to increase to approximately 18 million units. Due to stricter Corporate Average Fuel Economy (CAFÉ) standards in 2025, the need for lighter vehicle bodies is accelerating, and demand for aluminum suspensions is rapidly growing.

A joint venture of Kobe Steel, Mitsui & Co., Ltd. and Toyota Tsusho Corporation, KAAP is the top North American manufacturer of aluminum forged parts for automotive suspensions. In addition to Japanese automakers, KAAP has supplied forgings to many U.S. and European automakers in North America, receiving high marks for its quality products. As KAAP’s four mechanical forging presses had reached full operation, the company increased its production capacity to meet growing future demand. This capacity expansion consisted of the installation of a melting/casting line and two 6,300-ton forging presses. A 150,000 square-foot extension was constructed next to the existing plant to house the new equipment.

Investments Bolster Kobe Steel’s Global Supply Network

To grow its aluminum forged suspension parts business, Kobe Steel has created a production network that spans three countries: Japan, the United States and China. In Japan, forgings are made at the Daian Plant in Inabe, Mie Prefecture. In China, joint venture Kobe Aluminum Automotive Products (China) Co., Ltd. (or KAAP-China) supplies forgings from Suzhou, Jiangsu Province. KAAP’s latest expansion gives Kobe Steel the capacity to supply a total of 1 million pieces per month from the three locations.

In addition, KAAP-China will bring online a third mechanical forging press in autumn 2015. Kobe Steel decided on the expansion in March this year and construction of the 2-billion-yen investment is now under way. When construction of the third press is completed, KAAP-China’s capacity will increase from 250,000 pieces to 350,000 pieces per month. As a result, the Kobe Steel Group’s total production capacity will rise to 1.1 million units per month.

Future demand for aluminum suspensions is anticipated to grow mainly in two large markets: the United States and China. Kobe Steel will undertake timely capacity expansions at its plants to steadily capture this demand and build a strong position in the aluminum forged parts market for automotive suspensions.

Profile of Kobe Aluminum Automotive Products, LLC

Location: Bowling Green, Kentucky, USA

Established: May 2003 (Production began in 2005.)

President: Susumu (“Sam”) Koike

Employees: About 350 (increase of 50 after latest expansion)

Capital: $24 million

Shareholder composition:

Kobe Steel, Ltd. 60%

Mitsui & Co., Ltd. 25%

Toyota Tsusho Corporation 15%