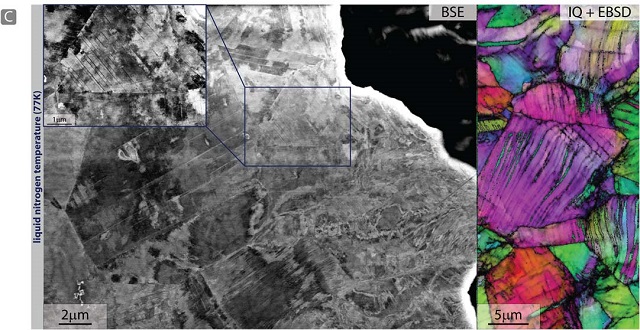

At 77K, back]scattered electron images taken in the wake of a propagated crack show the formation of pronounced cell structures resulting from dislocation activity that includes deformation]induced nano]twinning. (Courtesy of Ritchie group)

At 77K, back]scattered electron images taken in the wake of a propagated crack show the formation of pronounced cell structures resulting from dislocation activity that includes deformation]induced nano]twinning. (Courtesy of Ritchie group)

Researchers at U.S. Department of Energy’s Oak Ridge National and Lawrence Berkeley Laboratories have collaborated to synthesize a multi-element High-Entropy Alloy. The material properties of this new alloy improved at cryogenic temperatures, unlike most other materials. They found that the toughness, ductility and strength of the alloy improved at cryogenic temperatures.

Berkeley Lab materials scientist, Robert Ritchie, stated that the researchers studied the high‐entropy alloy, CrMnFeCoNi (chromium, manganese, iron, cobalt and nickel), which was made up of five major elements.

This alloy crystallized in the form of a single phase, face‐centered cubic solid. When tested, the alloy demonstrated very high fracture toughness, excellent tolerance to damage and above 1GPa tensile strength. These properties exceeded that of most other metallic alloys.

Traditional alloys contained a dominant element along with other minor elements and many required a second phase. The properties of these alloys were different from that of the individual elements. However, properties of high‐entropy alloys were not dependent on dominant constituents or other phases. When the count of alloying elements increased the configurational entropy also increased. These alloys stabilized into a single phase.

The researchers produced and characterized CrMnFeCoNi for microstructure, tensile properties, fracture and toughness. This high‐entropy alloy demonstrated spectacular values for fracture toughness and tensile strengths. At cryogenic temperatures, these values improved along with ductility. The researchers credit these properties to the “nano-twinning” phenomenon.

When plastic deformation takes place in materials at cryogenic temperatures, nano-twins are created. Nano-twinning deformation leads to continuous strain hardening which restrains any localized deformation that may cause early failure.

References

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.