A study conducted by a research team headed by Qunyang Li, a postdoctoral researcher at the University of Pennsylvania, has provided new insights into the friction properties of graphene.

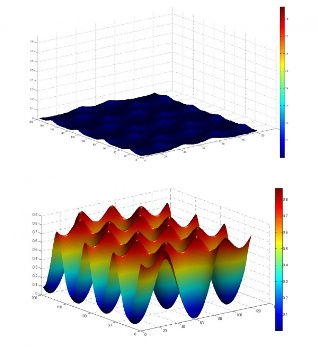

A comparison between the energy corrugation of graphene (above) and fluorinated graphene (below).

A comparison between the energy corrugation of graphene (above) and fluorinated graphene (below).

The addition of a fluorine atom to carbon-based materials on the macroscale produces non-stick, water-resistant surfaces such as Teflon. Conversely, the addition of fluorine to graphene on the nanoscale greatly increases the friction of the nanomaterial. This was discovered by the Penn team, through physical experiments and atomistic models, paving the way to better engineer and manipulate the surface properties of new advanced materials.

The Penn team tested graphene’s friction properties in collaboration with the Naval Research Laboratory (NRL) researchers, Jeremy Robinson and Paul Sheehan. The NRL scientists first discovered fluorinated graphene and have the expertise in making samples to desired specifications. Hence, the research team was able to add fluorine atoms systematically to the graphene samples and measure the degree of fluorination accurately.

To find the mechanism behind the frictional behavior of graphene, the Penn team approached Vivek Shenoy, a professor in Penn’s Department of Materials Science and Engineering. Xin-Zhou Liu, one of the researchers, said that the addition of fluorine atoms changed graphene’s energy corrugation landscape, introducing electronic roughness. This electronic roughness behaves like physical roughness on the nanoscale, thereby increasing friction, he added.

According to Robert Carpick, one of the researchers, this finding holds the potential to customize the friction property of graphene to a specific application. In addition, it will also help in gaining insights into the impact of the addition of elements such as oxygen and hydrogen on the surface properties of graphene, he concluded.

Nano Letters features the study results.