A team of researchers from Texas A&M University have revealed the work-hardening and plasticity properties of twinned aluminium with incoherent twin boundaries using an in situ nanoindentation technique.

Twin boundaries in nanotwinned metals help to maintain thermal stability, electrical conductivity and ductility, whilst also helping to improve mechanical strength. This has led to scientists becoming increasingly interested in studying the properties of nanotwinned metals. Earlier studies have predominantly concentrated on nanotwinned metals having low stacking-fault-energy and coherent twin boundaries.

However, the plasticity of twinned high stacking-fault-energy metals have previously not been very well understood. Materials with incoherent twin boundaries, such as aluminium, can be considered as high stacking-fault-energy metals.

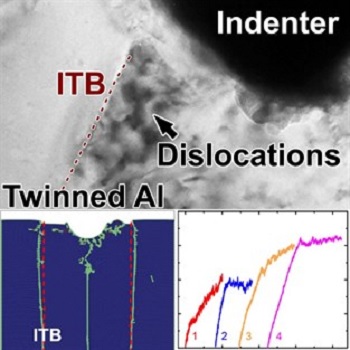

Molecular dynamics simulations and corresponding in situ nanoindentation studies were carried out using transmission electron microscopes on highly twinned aluminium. The researchers found a high plasticity and work hardening capacity in the material.

Further simulations showed that deformation mechanisms varied extremely between twinned aluminium and nanotwinned copper due to stacking-fault-energy controlled dislocation-incoherent twin boundary interactions. Dr Jian Wang from Los Alamos National Laboratory and Dr Haiyan Wang from Texas A&M University have co-authored this study which has been published in Nature Communications.