Nordson ASYMTEK, a Nordson company (NASDAQ: NDSN), a leader in fluid dispensing, jetting, and conformal coating technologies, will present the benefits of a conformal coating system with closed-loop process controls at SMTA International, Rosemont, IL, September 30-October 1, 2014, in booth #607. Controlling the conformal coating process, including tracking and traceability, ensures an extremely accurate, consistent, reliable coating result and increases productivity and yield.

"Nordson ASYMTEK has broad experience with conformal coating," said Per Orla Jensen, product manager, Nordson ASYMTEK. "We can help define the process that best suits each particular application. It's important to understand the layout of the board, where the keep-out areas are, and precisely where the coating should be placed. We have conveyorized systems for in-line production and systems for batch and single-piece demand flow production environments and can even configure the system with a UV oven and automated coating inspection."

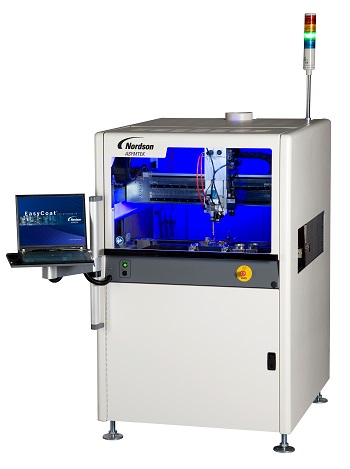

Nordson ASYMTEK's Select Coat® SL-940E Conformal Coating System will be demonstrated with a triple valve solution. It consists of the SC-400 PreciseCoat® jet, SC-280N non-atomized film coater, and DV-09 needle valve to suit any conformal coating application on the same board, whether it requires spray coating of an area or precision micro-coating of one particular part or wire. The system incorporates Easy Coat® software with continuous path motion control to blend stops and starts in the coating patterns. A wide range of process parameters can be monitored for statistical process control, including Nordson ASYMTEK's Laser Fan Width Control, Viscosity Control System, Bar Code System, and Flow Monitoring. Fluid and air pressure are set and monitored through software-controlled electronic regulators. The processes are automatically maintained within limits and process status is logged for traceability. This information can be exchanged with customer-specific Factory Information Systems (FIS).