A team of researchers have developed a novel method for manipulating the surface tension of liquid metals by applying very low voltages. This method holds promise for advanced reconfigurable antennas and electronic circuits.

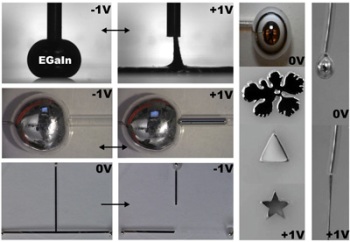

Liquid metals normally form a spherical shape due to their large surface tension. By applying a small voltage to the metal in water, a surface oxide forms on the surface of the metal and lowers the surface tension. Reversing the bias can remove the oxide and return the metal to a large surface tension. These phenomena can be utilized to control the shape of the metal and get it to flow in and out of capillaries. Click to enlarge. Image credit: Mohammad Khan.

Liquid metals normally form a spherical shape due to their large surface tension. By applying a small voltage to the metal in water, a surface oxide forms on the surface of the metal and lowers the surface tension. Reversing the bias can remove the oxide and return the metal to a large surface tension. These phenomena can be utilized to control the shape of the metal and get it to flow in and out of capillaries. Click to enlarge. Image credit: Mohammad Khan.

The technique is based on the fact that the removable oxide skin of the metal behaves similar to a surfactant, which reduces the surface tension between the fluid and the metal.

The researchers from North Carolina State University, used a gallium and indium liquid metal alloy for their study. The plain alloy possesses a high 500(mN)/m surface tension, which makes the metal form into a spherical blob. When a positive charge of less than 1V was applied, an electrochemical reaction occurs that leads to formation of an oxide layer on the liquid metal’s surface. This drastically reduced the surface tension to around 2mN/meter.

An NC State associate professor of chemical and biomolecular engineering, Dr. Michael Dickey, states that this change in surface tension made the liquid metal to spread, similar to a pancake, because of the gravitational force.

The research team demonstrated that when the polarity of the charge applied was changed to negative, the oxide was removed and the original high surface tension got restored. This proved the reversibility of the change in surface tension. The researchers found that changing the voltage in tiny steps could tune the surface tension.

Dickey, further states that the novel technique could be used to control liquid metal movement, that could find applications for completing/breaking circuits, modifying antenna shapes, MEMS, optical and photonic devices and in microfluidic channels.

Shape Reconfigurable Liquid Metal

In early studies, Dickey’s lab had shown a novel technique for 3-D printing of liquid metals, where the liquid metal maintained its shape by using the oxide layer that was formed in air.

This study has been published online in the Proceedings of the National Academy of Sciences.

References