This figure shows the injection needle array of a future liquid phase 3-D printer. Credit: ©Science China Press

This figure shows the injection needle array of a future liquid phase 3-D printer. Credit: ©Science China Press

Researchers at the Beijing Key Laboratory of CryoBiomedical Engineering described a new 3D printing method using low melting metal alloy ink. The melting point of the alloy is slightly more than room temperature. This liquid-phase printing technique is suitable for the manufacture of a conductive metal product in various dimensions. Unlike the traditional 3D printing, the liquid-phase printing technique is devoid of the air cooling process that results in oxidation of the metal.

3D metal printing is an evolving technology that has a number of potential uses including medical devices, functional electronics and other structural applications. Conventional 3D printing involves a great deal of time and is limited to high melting point metals.

According to the scientists, metals that melt at ambient conditions are widely used in microfluidics, thermal interface materials, and computer chip cooling applications. These materials are proved to be suitable for 3D printing technology and direct writing electronics.

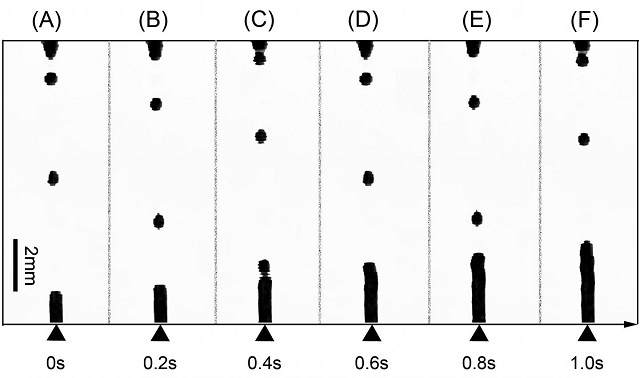

This chart shows the droplet deposition process (from A to F) in an ethanol cooling fluid. Image Crefit: ©Science China Press

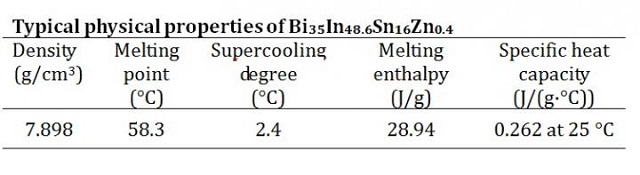

The researchers used a new four element alloy, Bi35In48.6Sn16Zn0.4 as the printing ink. They used a streamlined fabrication method involving 3D object generation in the form of a computer-aided design model and converting it to a STereoLithography (STL) file. The STL file is then uploaded to open source software program which creates horizontal layers of object and tool paths for each layer created. Following this, the printing ink is mixed with a liquid phase cooling fluid to print the object layer by layer.

The properties and types of printing ink can affect the 3D printing process. Metals with a melting point lower than 300°C can be generally chosen as printing ink, provided a suitable cooling fluid is used. The ink can be an alloy of indium, bismuth or gallium, or a mixture of alloys and nanoparticles.

This table shows the typical physical properties of Bi35In48.6Sn16Zn0.4. Image Credit: ©Science China Press

Liquid phase 3D printing technique has several benefits over the common metal prototyping methods. Three-dimensional structures can be formed using liquid-phase printing method at a high speed. The flow field and temperature field of the cooling fluid can be effectively controlled.

The combination of a conductive liquid metal and non-metal materials helps in the realization of 3D functional devices with conductive devices and supporting structures. Using this technique, it is possible to print 3D electromechanical systems.

The study is published in the SCIENCE CHINA Technological Sciences journal.

References