Oct 9 2014

Scientists at the Fraunhofer Institute for Surface Engineering and Thin Films IST in Braunschweig, Germany, have created the Megatron sputtering system that can produce a completely new range of coatings with better surface quality.

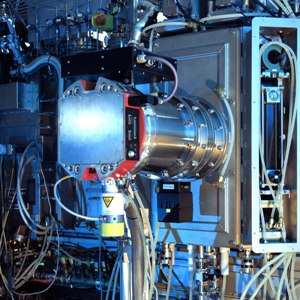

The Megatron enables the scientists at Fraunhofer IST to create new combinations of materials. (© Fraunhofer IST/Jan Benz)

The Megatron enables the scientists at Fraunhofer IST to create new combinations of materials. (© Fraunhofer IST/Jan Benz)

In regions where it is cold outdoors and warm indoors, triple glazing is used to prevent heat from escaping outside. However triple glazing has a flaw when outside temperature decreases during the night or in the early morning hours, making the panes of glass misty due to the condensation of moisture in the air. A conductive coating could rectify the condensation issue, but the coating would require the use of expensive indium tin oxide to make it scratchproof and weather proof.

Lead researcher Dr. Volker Sittinger stated that the solution for flaw-free, inexpensive triple glazing would be to use a solution containing titanium oxide, which is less expensive than indium but with lack of conductivity.

To make the coating material conductive, the researchers doped titanium with niobium at varying concentrations as required using the Megatron sputtering system. This yields a new coating solution that has a superior coating rate and comparatively smoother surface.

Megatron provides users with more options to alter doping concentrations, thereby enabling production of gradients and new multi-material coatings e.g., new self-cleaning surfaces for indoors using titanium dioxide and tungsten. Doping the titanium dioxide film with tungsten breaks down and removes organic dirt particles under sunlight exposure.

Megatron’s approach can also be adapted for other applications such as improvement of solar cell efficiency.