A new nonlinear acoustic method to detect the formation of cracks could help design lighter, thinner materials for aerospace.

Imaging acoustic nonlinearity not only provides sensitivity to smaller defects than is currently possible but may have the potential to detect damage before macroscopic material changes occur.

Dr. Jack Potter, University of Bristol

Although the concept of acoustic nonlinearity is known for its sensitivity to various physical properties such as mechanical damage and material microstructure, the absence of a proper imaging technique has prevented this concept from developing further.

At present, engineers can generate images of inner parts of a machine with the aid of ultrasound. Similar to identifying broken bones in the medical field, these images only reveal large issues like cracks in the parts, and not undetectable miniscule cracks.

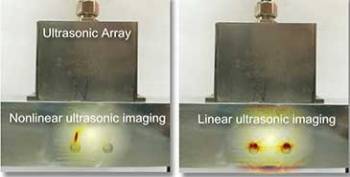

The team of researchers from the University of Bristol's Ultrasonics and Non-Destructive Testing (NDT) research group accomplished imaging of acoustic nonlinearity by making use of the different ways of propagation of fields created by sequential and parallel transmission of elements in ultrasonic arrays.

Research assisstant Dr. Jack Potter, who led the study, commented:

“Imaging acoustic nonlinearity not only provides sensitivity to smaller defects than is currently possible but may have the potential to detect damage before macroscopic material changes occur.

“This would enable intervention before cracks have even begun to form, as well as predicting the remaining life of an engineering structure. Crucially, the technique has been achieved using standard inspection equipment, which will allow for the rapid implementation of the technique in numerous applications.”

The crucial advantage of this development in NDT is that it will increase safety levels in structures, as well as aid in the creation of better structures such as sleek, lightweight aircraft in the coming years.

Sources