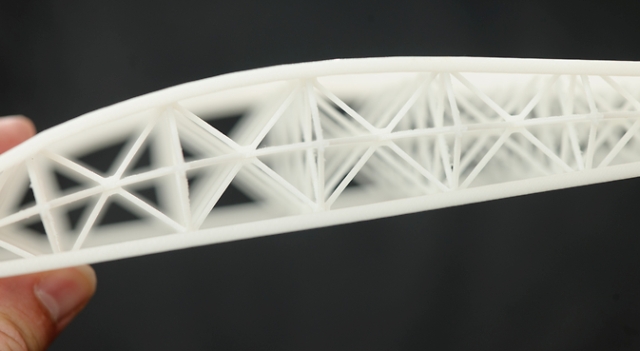

3D printed wing part for the FrankenEye aircraft. Image Credit: NASA/Ames/Dominic Hart.

Engineers at NASA's Ames Research Center, along with student interns, have successfully implemented 3D printed parts and components from surplus unmanned aerial vehicles (UAVs) into custom-built aircraft. Components from the Aerovironment RQ-14 Dragon Eye UAVs were used in this project.

The Dragon Eye aircraft can penetrate dangerous environments, such as volcanic plumes, as they are not affected by harsh environments. These aircraft, when unmodified, have twin electric motors, a wingspan of 3.75 ft, and weigh 5.9 lbs. They have the capacity to fly for an hour while carrying instruments weighing roughly 1.0 lbs.

The modified Dragon Eye UAV was dubbed “FrankenEye”, referring to Frankenstein's monster. The harvested parts were reanimated with new 3D printed parts to increase their endurance and payload capacity. For making the prototypes and the models, 3D printers at Stanford and Ames were used. Furthermore, 3D scanning technology was used for creating mechanical drawings and interface designs.

In order to improve aerodynamic efficiency and extend flight time, the wings were made longer and more slender. The newly designed parts were 3D printed at NASA Ames SpaceShop. Wing sections, winglets, wing ribs, nose cones, propellers and other components were 3D printed. Carbon fiber tubing and aluminum rods were then used to reinforce the wing sections.

The existing lithium-ion battery enabled a flight time of about an hour. The new design, with its efficient wing design and two batteries, enabled the modified planes to fly three times longer whilst carrying a higher payload.

Volcanologist David Pieri of NASA’s Jet Propulsion Laboratory is to lead the Costa Rican Airborne Research and Technology Application 2015 mission. Several modified Dragon Eye UAVs and the FrankenEye will be used to study the hazardous plume emissions from the Turrialba volcano. This mission will help improve the data obtained from satellites.

This news follows NASA's announcement of its "Game-Changing Development Program" just days ago inviting designers to write proposals for ultra-lightweight materials for use in aerospace applications.

NASA's recent mission to the International Space Station (ISS) using an unmanned Antares rocket on 28/10/2014 took a turn for the worst as seconds after liftoff the rocket exploded, completely destroying the vehicle, its payload and causing extensive damage to the landing pad.

Amongst the cargo in the rocket was the Planetary Resources' (an asteroid-mining firm) first ever spacecraft (Arkyd 3 Satelite) which was set to, upon arrival at the ISS, be launched into low-Earth orbit to test out avionics, vehicle control and systems for future asteroid exploration.

NASA Rocket Explodes Seconds After Launch in Virginia - RT America - YouTube