Dec 2 2014

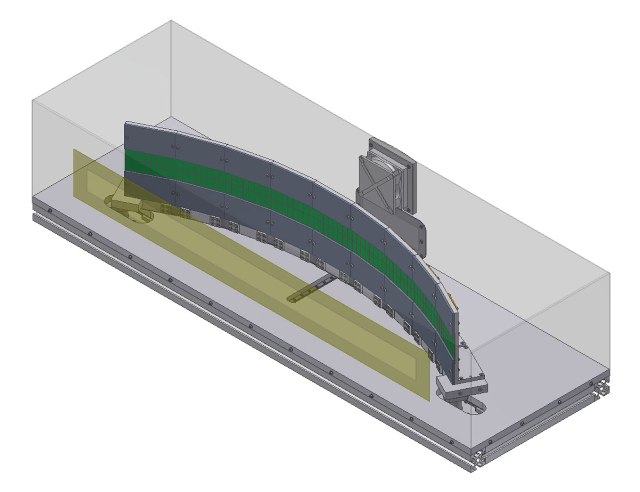

The MULIX X-ray detector is designed to be integrated into industrial computed tomography systems. This hybrid solution combines the advantages of single-line and flat-panel detectors. Its adjustable curvature enhances the image quality while mainaining full flexibility. © Fraunhofer EZRT

The MULIX X-ray detector is designed to be integrated into industrial computed tomography systems. This hybrid solution combines the advantages of single-line and flat-panel detectors. Its adjustable curvature enhances the image quality while mainaining full flexibility. © Fraunhofer EZRT

Scientists at the Development Center for X-Ray Technology EZRT have designed an advanced X-ray detector called MULIX, which may be incorporated into industrial computed tomography (CT) systems.

The X-ray detector is based on the design of medical X-ray machines. Their adjustable curvatures improve image quality and at the same time enables excellent flexibility, thus making it possible to adapt the device to different material properties and sizes of test objects.

Industrial X-ray machines, unlike medical X-ray machines, are used to study objects that differ in terms of materials and size composition. The aim was to integrate high image quality with excellent flexibility.

MULIX combines the benefits of flat-panel and single-line detectors and thus acts as a perfect hybrid solution. It delivers high-quality 3D images in real time, making it possible to rebuild the processes occurring inside the materials.

The new device is based on a detector having multiple lines, a unique design which so far has only been employed in the medical industry. Operating on the same principle as single-line detectors, multiple-line detectors cover larger areas and thereby bring down the scanning time.

MULIX uses 256 lines, which make it possible to scan car body parts and other large objects quickly and easily. Since the detector is capable of delivering images quickly, CT techniques can be used to make a 3D-scan of objects in real time.

When testing mechanical properties such as tensile strength, we can use the images we get to see just how a compromising fault comes about,

Frank Nachtrab from the EZRT, a division of the Fraunhofer Institute for Integrated Circuits IIS

The MULIX X-ray detector offers potential applications in research and quality assurance of materials, and can significantly benefit aerospace and automotive industries. Following promising results of the MULIX X-ray detector, the researchers are now seeking industrial partners to develop a prototype of MULIX.