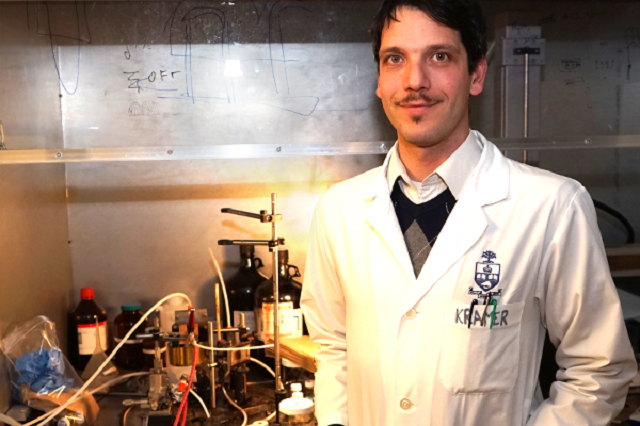

It may look more like Junk Yard Wars than high-tech, but U of T researcher Illan Kramer's (pictured) device is the first step towards spray-on solar cells.

It may look more like Junk Yard Wars than high-tech, but U of T researcher Illan Kramer's (pictured) device is the first step towards spray-on solar cells.

Researchers at the University of Toronto have developed a new method which uses colloidal quantum dots (CQDs) to spray solar cells onto flexible surfaces. This invention is a major advancement towards the production of low-cost spray-on solar cells.

Atomic layer deposition (ALD) is a thin-film deposition technique which involves the coating of a material in sequential layers of a substance which is just one-atom thick. The new system based on ALD is known as sprayLD. Surfaces with any shape can be coated using solar-sensitive CQDs, which are printed on flexible films. Practical examples include the wings of an aeroplane and even patio furniture.

Illan Kramer, a post-doctoral fellow with the Ted Sargent group in The Edward S. Rogers Sr. Department of Electrical & Computer Engineering at the University of Toronto commented: “My dream is that one day you’ll have two technicians with Ghostbusters backpacks come to your house and spray your roof.”

A CQD-coated film that is coated onto a surface area equivalent to that of a car’s roof can generate energy that would be sufficient to power 24 compact fluorescents or three 100W light bulbs. Currently, light-sensitive CQDs could be added onto surfaces only using batch processing. However, batch processing is a time-consuming and costly assembly-line method, which is also inefficient.

sprayLD - New technique offers spray-on power

Using the SprayLD method, a liquid that contains CQDs is sprayed onto a flexible surface directly. This method involves a roll-to-roll coating approach and enables easy integration of solar cells in production processes that are currently being used by the industry.

Kramer demonstrated that without significant effect to the solar-cell efficiency, the new sprayLD method could be used on flexible materials. This was described in papers published in Applied Physics Letters and Advanced Materials journals.

The sprayLD device was built using easily available and inexpensive parts. Kramer used regular air brushes used for art and a spray nozzle which was used in steel mills to cool steel using water.

This is something you can build in a Junkyard Wars fashion, which is basically how we did it. We think of this as a no-compromise solution for shifting from batch processing to roll-to-roll.

Illan Kramer, Post-Doctoral Fellow at the University of Toronto

The vice dean, research in the Faculty of Applied Science & Engineering at University of Toronto, Ted Sargent (ECE), commented that: “As quantum dot solar technology advances rapidly in performance, it’s important to determine how to scale them and make this new class of solar technologies manufacturable. We were thrilled when this attractively manufacturable spray-coating process also led to superior performance devices showing improved control and purity.”

Kramer, along with other researchers, used a Blue Gene/Q supercomputer that belonged to the Southern Ontario Smart Computing Innovation Platform (SOSCIP) in order to model the performance of sprayed CQDs and how they were equivalent or better than batch-processed products. This study has been published in the journal ACS Nano.