Scientists at EPFL have developed a simple and innovative method to make nanowires from a perovskite-structured material, which could aid in enhancing the efficiency of solar cells.

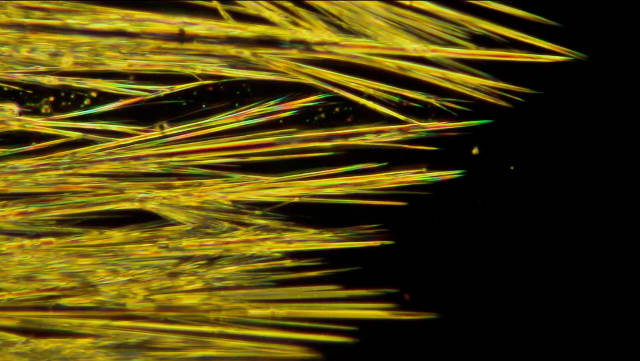

Perovskite nanowires grown by the "slip-coating" method. Image credit: Endre Horváth and László Forró, EPFL

Perovskite nanowires grown by the "slip-coating" method. Image credit: Endre Horváth and László Forró, EPFL

Nanowires are structures which are just a few nanometers across, but are much longer than they are wide - sometimes orders of magnitude longer. Depending on the material that they are made up of, nanowires could be used as semiconductors in computer chips, electronics and as insulators.

EPFL’s Endre Horváth and László Forró used a “slip-coating” method, which is a new, simple method for producing nanowires from perovskite materials - a class of materials which have attracted increased research attention in recent years due to their interesting material properties, including ionic conductivity and superconductivity. Up to now, however, perovskites have not been formed into nanowires.

The specific material used was methylammonium lead iodide (CH3NH3PbI3).This material, along with others of its class, are named perovskites after the mineral they share their basic crystal structure with.

Horváth was trying to grow crystals from this particular material that is considered a “superstar material” for energy related applications. This perovskite has a very high light-absorption efficiency due to its atomic structure, making it highly effective in Grätzel cells, or dye-sensitized solar cells.

Horváth was attempting to find out the types of nanostructures that could be made with methylammonium lead iodide. This material is a liquid and the researcher was trying to find out the optimum way to grow solid crystals from this liquid so that it could be used for various applications.

“I could grow it into flakes, needles, and cubic crystals, but these are large, macroscopic structures, so I tried to scale them down.”

Endre Horváth

Horváth was successful in producing crystals at the micrometer scale. Further, he was able to produce nanocrystals when he modified the pressure and temperature conditions. His colleague László Forró commented:

“We then wondered if I could elongate these nanocrystals to make nanowires. If we could texture this perovskite from loosly connected grains into nanowires, we could improve the performance of photovoltaic cells.”

Conventionally, the “blade-coating” method is used for elongating materials by spreading a liquid material over a surface so as to produce a very thin film. In this method, the gap between the surface and the blade is very wide and this factor does not allow production of nanometer thick structures.

Horváth took two simple glass coverslips that are normally used for sample viewing through microscopes. He placed the perovskite between the glass coverslips and then pressed the liquid material. Following this he slid them apart, and within a couple of seconds he observed the growth of needle-like structures. When the diameters of these structures were measured they were found to be in the nanometer scale. The researchers state that these are the first ever nanowires produced from perovskite. They have named this method of producing nanowires “slip-coating".

Growing Perovskite Nanowires

The researchers are now trying to standardize this method, and also scale it up so that it could be used in industrial and laboratory settings. “If we can make nanowires like this, it will open up a whole new subfield of technology, where we can make a number of optical tools, such as detector antennas, lasers or diffraction gratings,” says Horváth.

EPFL’s Laboratory of Physics of Complex Matter has collaborated with Attolight AG and the Hungarian Academy of Sciences for this study.

Sources and further reading