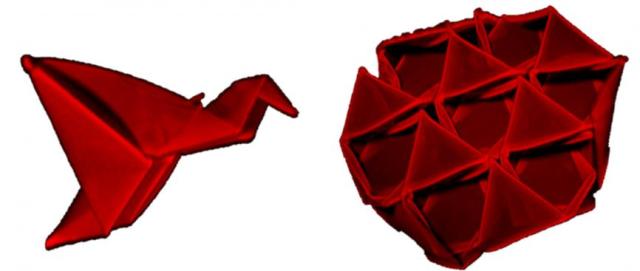

3D reconstructions (from confocal fluorescence microscopy) of self-folded origami structures with overall dimensions slightly below 1mm. At left is a bird based on the design “New Flapping Bird” by Randlett, and at right an octahedron-tetrahedron (‘octet’) truss design independently discovered by many origamists including Huffman, Kawasaki and Resch.

3D reconstructions (from confocal fluorescence microscopy) of self-folded origami structures with overall dimensions slightly below 1mm. At left is a bird based on the design “New Flapping Bird” by Randlett, and at right an octahedron-tetrahedron (‘octet’) truss design independently discovered by many origamists including Huffman, Kawasaki and Resch.

A team of researchers from UMass Amherst have developed a method of constructing self-folding reversible origami structures on small length scales using Ultraviolet photolithographic patterning on photo-crosslinkable polymers.

Over the last 15 years, several advancements have been made in constructing 3D structures using self-folding 2D sheets. This new research has created the most complex of structures ever to be made to date.

The creation of 3D forms by scientists has been inspired from the Japanese art of origami. Until now, the drawback has been the reliance on simple shapes which has hindered advancement of new applications in fields such as soft robotics, biomimetic systems and mechanical meta-materials.

The UMass Amherst research team led by Ryan Hayward has now provided an innovative approach, which may enable new discoveries. Their research findings are published in the January 2015 issue of Advanced Materials.

Hayward says, “We have designed and implemented a simple approach that consists of sandwiching a thin layer of a temperature-responsive hydrogel with two patterned films of a rigid plastic. The presence of gaps in the plastic layers allows for folding by a controlled amount in a specified direction, enabling the formation of fairly complex origami structures.”

The research team used a maskless lithographic method, based on a digital micromirror array instrument, in order to spatially pattern the crosslinking of the polymer films and then break up the uncross-linked areas using a solvent.

Image Credit: NRT / Shutterstock.com

The main reason for directly patterning the polymer films is because it is simpler to pattern many polymers layers with several different material properties in a few steps, rather than using a conventional photolithographic method based on a photoresist layer.

The new method created by these researchers can be applied in the fields of biomedicine or bioengineering, especially when building advanced self-deploying implantable medical instruments and influencing cell growth in complex tissues and organs.

According to the authors of the new technique, the data “suggest[s] a clear pathway for future improvements” in the minimum achievable size and maximum achievable complexity of self-folded structures, “simply by using thinner films to enable tighter curvatures, along with improved lithographic methods to allow for patterning of smaller folds.”

The step-by-step actuation of folds in a restricted sequence characteristic involved in conventional origami was avoided by the researchers. Instead they chose to rely on ’collapse’ arrangements where all folds are achieved almost concurrently.

“Collapse-type origami designs have not been thoroughly explored in the past because of the difficulty of actuating tens or hundreds of folds with human hands; our technique removes this restriction and we expect that with the actuation scalability provided by our technique, vastly more complex collapsible structures may now be readily explored.”

The authors of the study expect the innovative platform that they designed will be useful “for future studies addressing fundamental questions about the mechanics of self-folded structures, as well as for applications in microrobotics, biomedical devices and mechanical metamaterials.”