By Alexander Chilton

Image Credit: J. Adam Fenster / University of Rochester

A research team from the University of Rochester have successfully used lasers in order to produce super-hydrophobic metals without the use of conventional temporary coating techniques.

Super-hydrophobic materials are desirable for a number of applications such as anti-icing, rust prevention and sanitation. However, currently available hydrophobic materials require the use of chemical coatings in order to give a material water repellent properties.

The team of researchers at the University of Rochester, led by Chunlei Guo and Anatoliy Vorobye, have published their findings in the Journal of Applied Physics. In this paper they discuss the powerful innovative laser-patterning process which creates complex micro and nanoscale formations, allowing the metals to develop super-hydrophobic properties.

This new research is based on previous research carried out by the team in which a similar laser-patterning process was used in order to turn metals black. Guo explained that by using this process, the team was able to create multifunctional surfaces with not just super-hydrophobic quality but which also had a highly-absorbent optical quality.

Guo added that one of the big advantages of his team’s process is that “the structures created by our laser on the metals are intrinsically part of the material surface.” This means that they cannot be removed, with these patterns helping the metal to repel water.

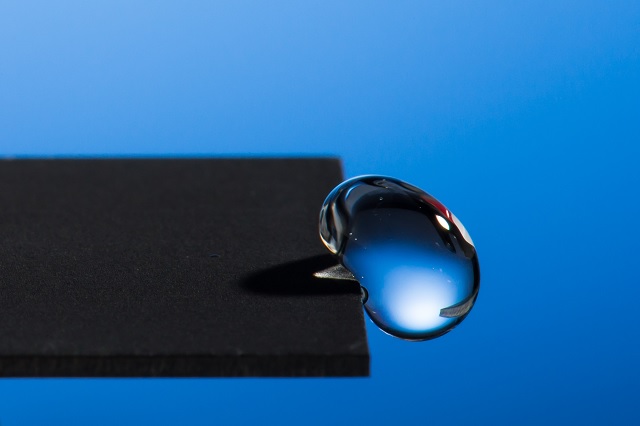

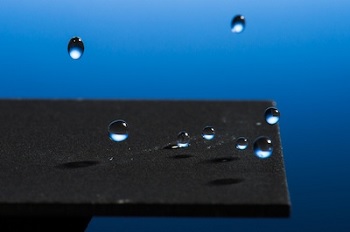

The material is so strongly water-repellent, the water actually gets bounced off. Then it lands on the surface again, gets bounced off again, and then it will just roll off from the surface.

Chunlei Guo, Professor of Optics at the University of Rochester

The materials developed by the scientists are a lot more slippery than Teflon, which is a hydrophobic material frequently used as a coating for non-stick frying pans. However unlike Teflon, these materials have the advantage of being super-hydrophobic. For instance, it would take a 70° tilt angle for water to roll-off a Teflon coated material but with the new super-hydrophobic material only a tilt of less than 5° is required.

Another advantage is that super-hydrophobic surfaces have a self-cleaning property. When water rolls off them, dust is also removed. In order to prove the superiority of this new innovative material, the scientists loaded the surface with dust from a vacuum cleaner. Using just three drops of water, nearly half the dust was removed. With 12 drops of water the entire surface was perfectly clean and the surface also remained completely dry.

Using Lasers to Create Super-hydrophobic Materials

Guo and Vorobyev used very powerful, ultra-short, laser pulses in order to transform the metal surface. The time duration of a femtosecond laser pulse is on the order of a quadrillionth of a second, however it reaches peak power equal to the complete North American power grid during its short burst.

“In these regions, collecting rain water is vital and using super-hydrophobic materials could increase the efficiency without the need to use large funnels with high-pitched angles to prevent water from sticking to the surface,” said Guo. “A second application could be creating latrines that are cleaner and healthier to use.”

Generally it is difficult to keep latrines clean in areas with a poor water supply. Using the new super-hydrophobic material when designing a latrine, it would be possible in order to eliminate the need for flushing with water.

Image Credit: J. Adam Fenster / University of Rochester

Image Credit: J. Adam Fenster / University of Rochester

However the scientists have many challenges to handle before this kind of application can reach the market.

One aspect is that it takes about one hour to pattern a 1 x 1inch metal piece, thus speeding up this process would be crucial before it can be applied in developing countries.

Guo believes that this technique can result in multifunctional metals. As metals are naturally good light reflectors, they have a shiny luster. By making them black, it would be possible to transform them into very efficient light absorbers.

Integrating light-absorbing properties with water repellent metals will open new avenues in order to produce better solar panels which are free of rust and do not require hours of cleaning. The team at the University of Rochester are keen on using this technique on non-metals such as semiconductors or dielectrics in order to pave the way for water repellent electronics in the future.