Image Credit: Shelby Kardell

Researchers at the University of Missouri have designed a new material that is capable of controlling elastic waves which travel through air. This latest breakthrough could provide promising applications in military, medical and imaging fields.

Examples of elastic waves include sound waves that travel through the air, shockwaves from earthquakes or the ripples created when an object breaks a body of water. Elastic waves have the ability to pass through a material or at the surface without causing any lasting changes to the structure of the substance.

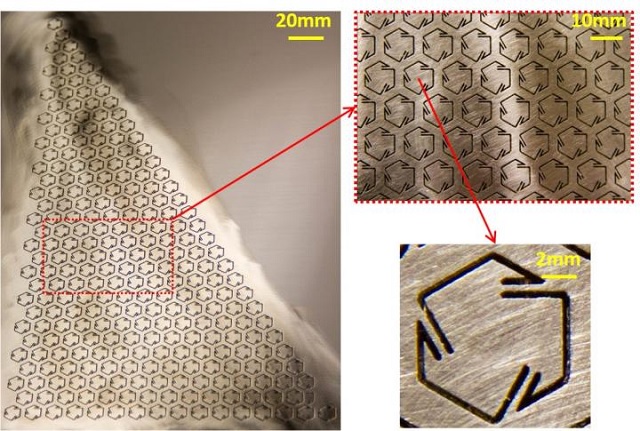

Previously, researchers have used materials such as rubber and metal in order to bend and control waves effectively. Guoliang Huang, along with other researchers at the University of Missouri, developed a single sheet material using steel and lasers to engrave geometric microstructure patterns (chiral) that are irregular to their mirror images.

“Methods of controlling and manipulating subwavelength acoustic and elastic waves have proven elusive and difficult; however, the potential applications--once the methods are refined--are tremendous.”

Guoliang Huang, Associate Professor of Mechanical and Aerospace Engineering in the College of Engineering at University of Missouri

This structural material is capable of controlling the increase of elastic or acoustical waves and is the first material to be made out of a single component. It also offers immense design possibilities such as super-imaging devices and enhanced broadband signals.

The researchers are planning to introduce elements that can be controlled easily and which could ultimately be used in a wide range of applications and fields.

Huang went on to say: “Our team has developed a material that, if used in the manufacture of new devices, could have the ability to sense sound and elastic waves. By manipulating these waves to our advantage, we would have the ability to create materials that could greatly benefit society--from imaging to military enhancements such as elastic cloaking--the possibilities truly are endless.”

Image Credit: Guoliang Huang

“In its current state, the metal is a passive material, meaning we need to introduce other elements that will help us control the elastic waves we send to it. We're going to make this material much more active by integrating smart materials like microchips that are controllable. This will give us the ability to effectively 'tune in' to any elastic sound or elastic wave frequency and generate the responses we'd like; this manipulation gives us the means to control how it reacts to what's surrounding it,” said Guoliang Huang.

The material could lead to many applications such as in medical and acoustic hearing devices, super-resolution sensors and a ‘super lens’ which could considerably improve super-imaging devices, all due to the possibility of directly focusing elastic waves.