Jan 31 2015

UOP LLC, a Honeywell company, announced today that China commissioned its second unit to produce propylene, a key ingredient in plastics, using its C3 Oleflex™ process technology.

Worldwide Propylene Gap . (Source: Honeywell)

Worldwide Propylene Gap . (Source: Honeywell)

Zhejiang Shaoxing Sanjin Petrochemical Co., Ltd. became the second company in China to commission a UOP C3 Oleflex process unit to produce propylene from propane, increasing the global production capacity from UOP technology to approximately 3.8 million metric tons annually (MTA).

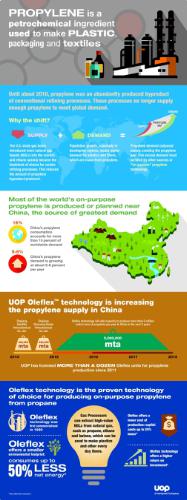

Traditionally, propylene is a byproduct of certain refining processes, but those processes no longer produce enough propylene to meet rising global demand. This propylene shortage has sparked investment in technology to create propylene from propane, also known as on-purpose propylene.

Since 2011, UOP has licensed the C3 Oleflex process to more than a dozen producers to meet rising demand, with a majority of licensed capacity in China. China is the world's largest energy consumer and its propylene consumption accounts for more than 15 percent of worldwide demand, which is growing at about 5 to 6 percent per year.

"By 2020, 20 percent of the world's propylene production is expected to come from on-purpose propylene production technologies, and UOP is proud to be leading the development of this essential petrochemical with our Oleflex technology," said Pete Piotrowski, senior vice president and general manager of UOP's Process Technology and Equipment business. "For more than 20 years, the Oleflex process has been a reliable, independent source of high-quality propylene and we look forward to helping increase its availability in China and around the world."

In addition to technology licensing, UOP also provided engineering design, catalysts, adsorbents, equipment, staff training and technical service for the project. Equipment supply included Callidus Low NOx (Callidus Stage Gas Ledge Stabilization) burners, manufactured at UOP Callidus Shanghai, which feature a patented tile configuration to achieve a "stiffer" flame.

Zhejiang Shaoxing Sanjin Petrochemical Co., Ltd. will produce 450,000 MTA of propylene at its facility in Shaoxing City, Zhejiang Province, China. Zhejiang Shaoxing Sanjin Petrochemical Co., Ltd. is a fully owned subsidiary of Zhejiang Fuling Holding Group, located in Shaoxing City, China. Established in 2003, the company specializes in polypropylene production and produces 600,000 metric tons of the substance annually.

"We selected UOP Oleflex technology for our propylene production needs due to its reliability, economics, experience in integrating with polypropylene technologies, and overall processing flexibility," said Mr. Zhong Jianming at Zhejiang Shaoxing Sanjin Petrochemical Co., Ltd. "UOP's local service and support team worked well with our team to make the start-up a success."

Oleflex technology has been a leading technology for converting propane to propylene for more than 20 years. The C3 Oleflex process uses catalytic dehydrogenation to convert propane to propylene. Compared with competing processes, UOP's C3 Oleflex technology provides the lowest cash cost of production, the highest return on investment and the smallest environmental footprint. This superior performance is characterized by low capital cost, high propylene yields, low energy and water consumption, and use of a fully recyclable platinum alumina-based catalyst system. In addition to the C3 Oleflex process, UOP also licenses its C4 Oleflex technology, a butane dehydrogenation process to convert isobutane to isobutylene.