Feb 16 2015

The consumer is more and more aware of quality, especially when buying food or pharmaceuticals. Therefore the overall appearance is quite a big decision criterion. A sufficient inspection of the packaging increases the customer's confidence and therewith also the sales figures.

For automated inspection also mechanical engineers are more and more convinced of image processing solutions, as machine vision technology has advantages for productivity and efficiency. At fully automated packaging machines and bottling plants, for example, the contents of the product is inspected dependably with extremely high clock frequency, which diminishes the error ratio and also saves money.

The EyeVision software is the evaluation software behind the smart cameras or also behind PC-solutions. Together with hardware, which supports EyeVision, such as e.g. the EyeCheck smart camera series, several inspections can be carried out.

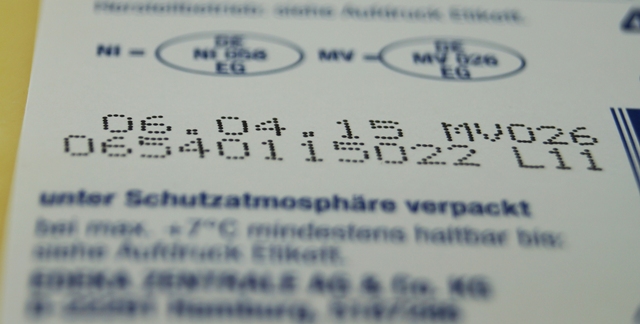

The visual inspection not only detects errors in transparency film and heat-sealed joints, but also the correct position of printed backing film and labels. Additionally the system can check the expiration date, as well as the bar code and the print layout. For example: EyeVision can with the KeyMatch command for pattern matching, detect the label and its pattern in any position and rotation. Also OCR reading can be carried out even when the label is askew.

The innovative image recognition and evaluation system EyeCheck detects exactly the texture of the inspected objects. Therefore an incorrect print is recognized and ejected from the production line in no time at all.

Application fields for EyeVision and EyeCheck are not only in the food and pharmaceutical industries, but also in the electronic and cosmetic industries as well as in the retail trade.