A joint research team from Technion-Israel Institute of Technology and the Massachusetts Institute of Technology has drawn inspiration from fish scales to create a radical material which balances outstanding anti-penetration characteristics with flexibility.

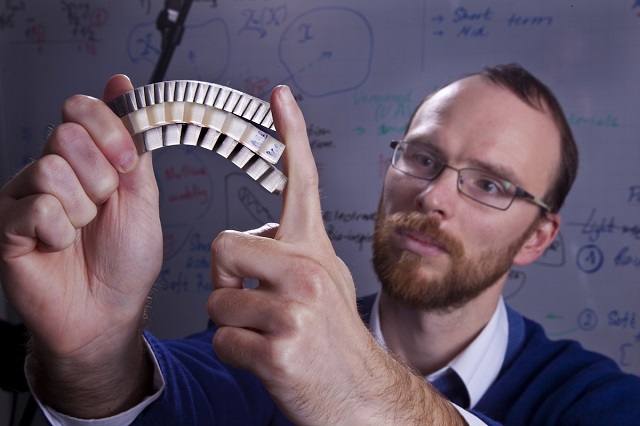

“The secret behind this material is in the combination and design of hard scales above with soft, flexible tissue below,” says Technion Assistant Professor Stephan Rudykh, pictured here.

“The secret behind this material is in the combination and design of hard scales above with soft, flexible tissue below,” says Technion Assistant Professor Stephan Rudykh, pictured here.

This exceptional material has the potential for applications in the manufacture of space suits capable of withstanding micro-meteorites and radiation during spacewalks, and also for bulletproof clothing for military personnel.

The research findings, containing details about the properties, uses and test results of this novel material, were published online by the Royal Society of Chemistry's technology journal Soft Matter on February 20. The research was led by the head of the Technion’s Mechanics of Soft Materials Laboratory, Assistant Professor Stephan Rudykh.

Many species of fish are flexible, but they are also protected by hard scales. Taking inspiration from nature, we tried to replicate this protecto-flexibility by combining two layers of materials – one soft for flexibility and the other with armor-like scales. The secret behind this material is in the combination and design of hard scales above with soft, flexible tissue below.

Professor Stephan Rudykh

Prof. Rudykh explained that usually, strength and flexibility are properties that compete with each other, and can never be found together. However, the joint research team determined a method to raise the penetration resistance by a factor of 40 while only reducing the material’s flexibility by a factor of five.

For instance, while manufacturing a combat military uniform, areas requiring flexibility such as the knees and elbows can be designed with more flexibility, while areas requiring anti-penetration properties, for instance in the upper body, can be strengthened.

“That attribute allows for the fabric to be tailored to the wearer’s body and the environment that the wearer will be facing,” explained Prof. Rudykh, who carried out post-doctoral studies at MIT, where he worked with 3D printing technology before joining the Technion. “This work is part of a revolution in materials properties. Once we can gain control over a material’s micro properties, using 3D printing we can create materials of an entirely different type, each with the ability to be adjusted to fit the wearer, the need, and the environment.”

The researchers have carried out preliminary material testing and are advancing to perform dynamic analysis using rapidly moving projectiles, such as small particles and bullets. They will also undertake analysis of the flexibility feature under pressure.

“Our findings provide new guidelines for developing simple material architectures that retain flexibility while offering protection with highly tunable properties,” concluded the researchers. “The tailored performance of the protective system – with characteristics that can be tuned according to the required movements at different regions of the body – draws its abilities from the microstructural geometry. The ability for a given microstructure to offer different deformation resistance mechanisms is key to achieving the multifunctional design of stiff plates and soft matrix. We found that careful selection of microstructural characteristics can provide designs optimized for protection against penetration while preserving flexibility.”

The U.S. Army Research Office supported the research through the MIT Institute for Soldier Nanotechnologies.