The next generation of Coperion’s STS twin screw extruders is making its world public debut at Chinaplas 2015 (Guangzhou / PR China, May 20-23, 2015). The new STS Mc11 series features an increase in torque from 10 to 11.3 Nm/cm³ and for the first time is part of Coperion’s industry-proven ZSK MEGAcompounder method patent.

When it comes to compounding with high energy input, the new STS Mc11 series provides increased throughput by up to 27 % as well as decreased melt temperature due to higher screw filling, thus improving the quality of the resulting compound. The new STS Mc11 series is exclusively equipped with high quality European gearboxes. Screw speed has been increased from 800 to 900 rpm. To improve cleaning and quick change for masterbatch applications, the STS Mc11 is equipped with new hoppers with inserts and a redesigned die head. The screw shaft coupling is similar to the time-tested design of the ZSK Mc18 series. Coperion presents the new STS 65 Mc11 twin screw extruder together with a feeder from Coperion K-Tron at Chinaplas 2015 on their booth no. 5.1K11 in hall 5.1.

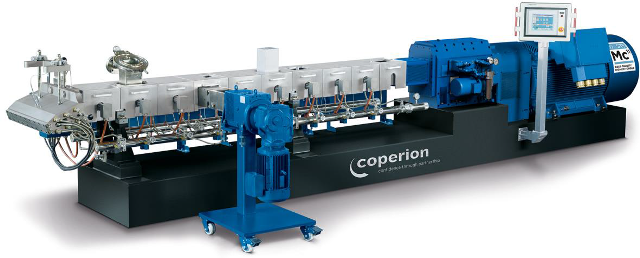

The new Coperion STS Mc11 series with increased torque of 11.3 Nm/cm³ is equipped with new Coperion-branded gearboxes from renowned European suppliers. Photo: Coperion, Stuttgart

The new Coperion STS Mc11 series with increased torque of 11.3 Nm/cm³ is equipped with new Coperion-branded gearboxes from renowned European suppliers. Photo: Coperion, Stuttgart

New Coperion-branded gearboxes for STS Mc11 series

The STS Mc11 series will be equipped with Coperion-branded gearboxes, which will also be used in the medium torque version of the ZSK series. The gearbox redesign project was initiated and driven by Coperion experts together with well-known European suppliers. The new design is a result of Coperion’s extensive experience with the set-up and service of gearboxes gathered over the past decades. By branding the new gearboxes Coperion is taking full responsibility for design, engineering and service. Coperion will act as the direct contact for all issues regarding the gearboxes, including customer documentation and after sales service. The service group has skilled technicians and quickly available spare parts for customers all around the world.

New base frame of STS Mc11 for increased operating safety

To increase stiffness during operation with a torque of 11.3 Nm/cm³, the STS Mc11 series is equipped with a totally redesigned base frame (finite element method). This base frame dampens vibrations and ensures smooth operation of the twin screw extruder. It increases operation safety and promotes long service life of the extrusion system.

Improved quality standards at Coperion in Nanjing

During the development process of the new STS Mc11 series, Coperion Nanjing, China - the production site of the STS series - has undertaken comprehensive initiatives to improve its quality standards. Coperion Nanjing is now using state-of-the-art German machining centers and time-tested Coperion quality production standards have been implemented. The entire production and assembly process is closely controlled by Quality Check Points and Factory Acceptance Tests (FAT) using high-precision, high-level German production and quality measuring machinery and equipment.