Featuring special high thermal conductive fillers, Master Bond EP48TC is two part epoxy paste that can be applied in bond lines as thin as 10-15 microns.

This material offers exceptionally low thermal resistance of 5-7 x 10-6 K·m2/W, which imparts impressive heat transfer capabilities and thermal conductivity of 20-25 BTU·in/ft2·hr·°F [2.88-3.60 W/(m·K)].

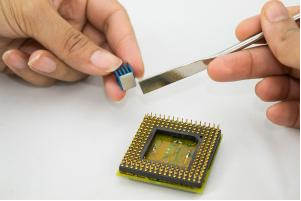

It can be used in applications in the aerospace, electronic, optical, specialty OEM and many other high-tech industries.

EP48TC has a tensile lap shear strength ranging from 900-1,100 psi and bonds well to a wide variety of substrates, including metals, composites, glass, ceramics and many plastics. Even in thin sections, its strength retention is outstanding. It also has a low coefficient of thermal expansion, low shrinkage upon curing and excellent dimensional stability.

EP48TC has a forgiving 100 to 40 mix ratio by weight, or 100 to 50 mix ratio by volume. The working life for a 100 gram batch at 75°F is 90-120 minutes. The epoxy cures at room temperature or more quickly at elevated temperatures. It is serviceable over the temperature range of -100°F to +300°F. The color of Parts A and B is gray. EP48TC is available in standard packaging ranging from ½ pint to 5 gallon container kits.

Master Bond Adhesives for Heat Dissipation Applications

Master Bond EP48TC is a two component epoxy with high thermal conductivity that can be applied in very thin sections. Read more about Master Bond’s liquid thermal interface materials at: www.masterbond.com/properties/thermally-conductive-epoxy-adhesives