Leaders in containment technology, Hosokawa Micron Ltd, are now offering customers the opportunity, at design stage, to accurately check, how the placement of objects, equipment and operatives in their downflow booth may affect airflow patterns and containment all important to the achievement of critical OELs.

Using the latest computerised airflow dynamics simulation software, that displays 3D flow animations, Hosokawa Micron engineers are able to develop individual downflow booth designs that ensure workplace protection from potentially harmful dusts and vapours is the best it can be.

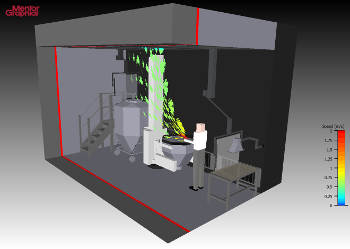

Advanced computer modelling provides a visual demonstration of local extract as part of a downflow system.

Advanced computer modelling provides a visual demonstration of local extract as part of a downflow system.

This leading edge airflow dynamics modelling package complements Hosokawa Micron’s existing ergonomic modelling to combine to deliver the most appropriate downflow booth solution to meet the customer’s needs and working practices.

Explains Carl Emsley, Hosokawa Micron Ltd, ‘Customers can see for themselves how airflow in the booth can be effected by protective screens, local extract ventilation, ancillary equipment, as well as the presence of an operative. The simulations represent conditions under normal established operations – starting with an empty booth demonstrating the down flow with primary ventilation system running. Further simulations can then be created to demonstrate how airflow would change when equipment or operatives are brought into the booth – this means Hosokawa Micron engineers can optimise positioning of equipment and operations within the booth; right at early design stage.

Using the airflow simulation package allows Hosokawa engineers to produce a proven downflow booth design for both standard and non-standard units and is invaluable when designing for complex, multi-use operations.

With this software not only can we see the clear airflow patterns but workers can also see for themselves how they will be protected when handling potentially hazardous materials, giving them confidence in the task they are required to undertake. We can also say that in installations where downflow booths are placed within cleanrooms, where sometimes the ventilation systems can conflict, this new software is proving invaluable.’