Expensive cover glass may have reached its peak in scratch resistance and anti-reflectivity. That’s why mobile device manufacturers are looking to new coating solutions for the answer. SCHOTT’s new “Hard & Clear” coating solutions increase scratch resistance by more than 95 percent and reduce glare by 85 percent. Manufacturers can apply this new coating to any cover glass to give mobile devices a virtually scratch-free glass screen that users can see clearly even in direct sunlight.

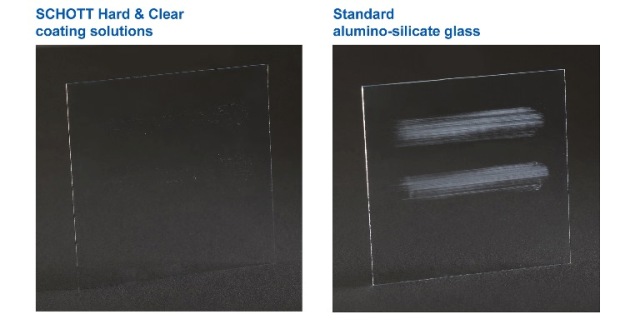

SCHOTT’s Hard & Clear coating type I “ultra hard” offers excellent scratch resistance, reducing more than 95 percent of all scratches that would normally appear on standard alumino-silicate glass. Image: SCHOTT.

SCHOTT’s Hard & Clear coating type I “ultra hard” offers excellent scratch resistance, reducing more than 95 percent of all scratches that would normally appear on standard alumino-silicate glass. Image: SCHOTT.

“Smartphone owners know better than anyone that current cover glass is not getting the job done. Coatings, not cover glass, will set a new standard in mobile screen scratch resistance and anti-reflectivity. SCHOTT’s new Hard & Clear coatings keep cover glass virtually scratch- and glare-free. These coatings outperform all other available options, maintaining a more pristine mobile screen and a better experience outdoors,” said Lutz Gruebel, Head of Sales & Marketing of SCHOTT’s cover glass business.

SCHOTT’s two breakthrough hard coating solutions include “ultra hard” and “durable anti-reflection” options. Type I, the ultra hard coating, reduces scratches by more than 95 percent over traditional alumino-silicate cover glass, achieving performance close to that of sapphire. This coating also cuts reflections by 75 percent.

Type II, the durable anti-reflection coating, reduces reflection by 85 percent and scratches by 90 percent over alumino-silicate cover glass. The coating’s residual air/glass reflection of only 0.6 percent means it’s the best anti-reflective coating available for smartphone usage, making it possible to read a message outside in direct sunlight.

First, the coatings underwent the standard industry steel wool abrasion test. A weight load of 1 kilogram was applied to a 10 millimeter by 10 millimeter piece of steel wool type #0000, rubbing the steel wool at a speed of 40 cycles per minute. The coating stayed intact for 10,000 abrasions cycles—three times more than the standard test requirement.

In addition, the coatings underwent a fierce new sandpaper test with very hard corundum sandpaper at a force of 2 kilograms and 50 oscillations. This is a trial specifically designed by SCHOTT to mimic the long and deep scratches that come from keys, coins, and sand—the enemy of all mobile devices kept in handbags and pockets. This test also measures the scratch level accurately with a hazemeter and benchmarks the results with other solutions.

“The results of the testing are conclusive: With a reduction of more than 95 percent in scratches, any cover glass treated with our innovative coatings will outperform all other products available,” said Gruebel.

SCHOTT will offer this innovation for all glass substrates, whether alumino-silicate or soda lime glass, to all manufacturers. SCHOTT licenses its technology to coating specialists. The first licensing partner, the Chinese display coating specialist ZhengXing, is scheduled to begin mass production of Hard & Clear coated cover glass in July 2015.

“Producing an anti-reflective coating that is highly durable, extends scratch resistance dramatically, and can be produced in a stable mass production process is a true first in the mobile device industry,” added Gruebel. SCHOTT engineers and technical experts are supporting the ramp-up on site with technological expertise and quality surveillance.

For more information: http://www.us.schott.com/xensation/english/products/hard-coating-solutions.html

See the new video: https://youtu.be/6hnPzrOMtJk