May 29 2015

University of Leicester researchers have that for reproducing textured surfaces, rubbers with a more fluid formulation are more reliable than those that are thick and sticky.

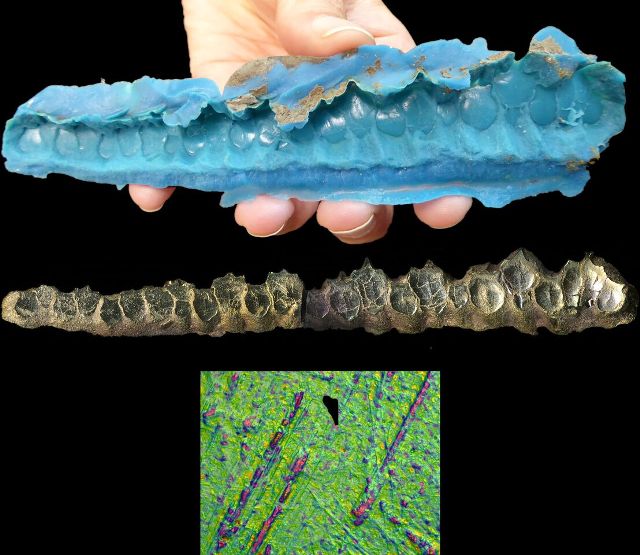

A high fidelity rubber mould of hadrosaurid dinosaur teeth, with a gold coated replica for measurement of roughness of the tooth surfaces. The surfaces have scratches that were created as the dinosaur fed on vegetation 67 million years ago, and measuring the roughness can reveal what kind of food they ate. The original teeth are too large to transport to the instrument that measures roughness.

A high fidelity rubber mould of hadrosaurid dinosaur teeth, with a gold coated replica for measurement of roughness of the tooth surfaces. The surfaces have scratches that were created as the dinosaur fed on vegetation 67 million years ago, and measuring the roughness can reveal what kind of food they ate. The original teeth are too large to transport to the instrument that measures roughness.

In scientific analysis, rubber compounds are commonly used for creating textured surface copies and moulds. However, until now, few studies have been conducted to determine the most suitable rubber for reliable reproduction.

Professor Mark Purnell from the University of Leicester’s Department of Geology, who led the study, explained: “Roughness is something that everyone understands, and the difference between a rough and a smooth surface is obvious, but how do you compare two rough surfaces? How can you tell if surfaces – of the cylinders in your car engine, for example - are smooth enough to perform as they should?

“If you need to make precise measurements of a surface, and you can’t take the original surface to the measuring instrument, you would need to analyse a replica. What we haven’t known until now is whether the quality of the replica varies depending on the rubber used.”

The Leicester research team set out to find the kind of rubber that would help create the best replica. They tried out various rubber compounds and created numerous copies of smooth and rough surfaces. The rubber was mixed and then poured on to a surface, where it solidified. The team then analyzed the replicas, comparing them against one another and the original surface.

The researchers observed that the rubber replicas were incomparable. Furthermore, when rubber compounds with high viscosities were used, the replicas obtained were less similar to the original surface as they poured as thick liquids. Hence, highly viscous rubber compounds are not desirable for reproduction.

The lead author of the paper, Robert Goodall, a University of Leicester PhD student, added: “If you want good results – with all the ridges and bumps on a surface reproduced at the same scale as the original - you need to use the right rubber for the job.”

Engineers and scientists make copies of the surfaces of superconductor components, archaeological tools, forensic tools, teeth, skin and other objects for their investigations. The surfaces of the object are carefully measured in order to quantify their texture and roughness. However, this is not always not be easy.

In car engines, surface roughness plays a very important role. The engine’s cylinders must have “just sufficient” roughness so that a film of lubricant sticks to its surface. However, if the engine’s cylinders are very smooth, then the engine would seize.

Researchers have developed techniques that can take nanoscale measurements of dimples, bumps and ridges.

This study has been published as a paper titled ‘Accuracy and Precision of Silicon Based Impression Media for Quantitative Areal Texture Analysis,’ in the Scientific Reports journal.

The Natural Environment Research Council has provided funding for this study.