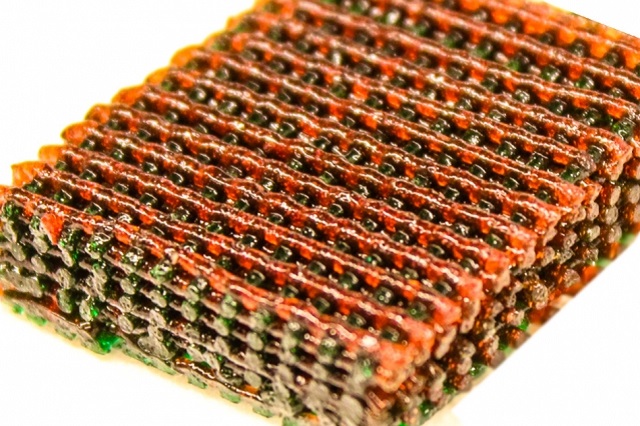

Photo shows the open lattice of 3D printed material, with materials having different characteristics of strength and flexibility indicated by different colors. (Courtesy of the researchers)

Photo shows the open lattice of 3D printed material, with materials having different characteristics of strength and flexibility indicated by different colors. (Courtesy of the researchers)

MIT researchers have developed a new method of converting strong, yet wet and soft, biocompatible materials commonly known as hydrogels into complex and intricately patterned structures. The process can result in injectable materials that can be used for delivering cells or drugs into the body, durable but flexible structures for robotic applications and scaffolds to regenerate load-bearing tissues.

The research co-authored by MIT associate professor of mechanical engineering Xuanhe Zhao and colleagues at MIT, Duke University, and Columbia University was published in the Advanced Materials journal.

Zhao said that the new method can result in extremely tough and complex hydrogel structures that are compatible with the encapsulation of cells in the structures. This could enable production of complex 3D hydrogel structures which, for instance, can be infused with cells and drugs and inserted into the body.

Hydrogels are water molecules embedded in rubber polymer networks which provide proper shape and structure. They are identical to natural tissues such as cartilage which is used as a natural shock absorber in the body. The new 3D printing process could help in artificial production of tough hydrogel structures for repair or replacement of load-bearing tissues like cartilage.

In general, synthetic hydrogels are weak or brittle. However, a number of tough and stretchable synthetic hydrogels have been produced during the last decade. Zhao stated that the traditional way of fabricating tough hydrogels would involve “harsh chemical environments” that may kill living cells.

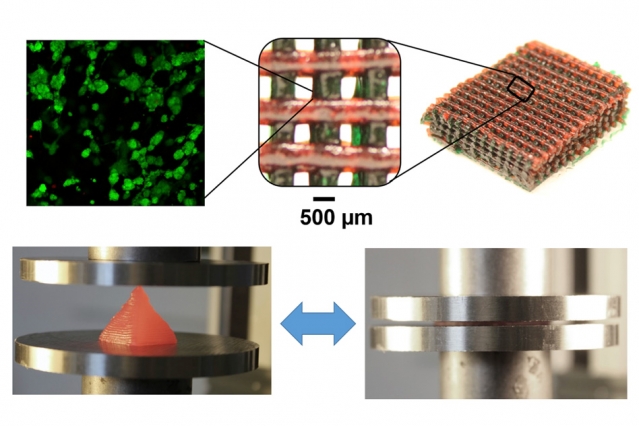

The new materials can however be synthesized together with living cells like stem cells, enabling high viability of the cells. Zhao, who holds a joint appointment in MIT’s Department of Civil and Environmental Engineering, added that complex 3D structures with tough hydrogels could not be produced in the previous work. The new tough hydrogel can be easily printed on different 3D structures like a multilayer mesh, twisted bundle, physiologically relevant shapes including a human nose or ear, pyramid, hemisphere or hollow cube.

The new method makes use of a 3D printing mechanism which is commercially available.

The innovation is really about the material — a new ink for 3-D printing of biocompatible tough hydrogel — specifically, a composite of two different biopolymers. Each [material] individually is very weak and brittle, but once you put them together, it becomes very tough and strong. It’s like steel-reinforced concrete.

Zhao

The elasticity of the printed material is a result of one of the two polymers, while the other helps in spreading the energy under deformation without damage. A third constituent, biocompatible “nanoclay” enables fine-tuning of the viscosity of the material and enhancing the flow control via the 3D-printing nozzle.

Sungmin Hong, a lead author of the paper and a former postdoctoral in Zhao’s group, said that the flexibility of the material can be extended such that any printed shape can be compressed up to 99% and released back to achieve its original shape. Further, the material can be stretched to five times its original shape. Thus, resilience is a key parameter of natural tissues in body, which helps in withstanding a number of impacts and forces.

These materials could be eventually applied in custom-printing of different shapes for the replacement of cartilaginous tissues in load-bearing joints, noses and ears. Laboratory results have already proved that the material is tougher than natural cartilage.

At top, the structure of the hydrogel material is shown at different scales, down to the molecular level. At bottom, material 3-D printed using this method is so flexible that it can be squeezed flat, and then spring back to its full original shape.

Image Credit: Courtesy of the researchers

The researchers are further working to improve the printer resolution that is restricted to only 599um size details as of now, and to apply the printed hydrogel structures in animals. Zhao said, “We are enhancing the resolution to be able to print more accurate structures for applications.”

Beside biomedical applications, the same method could also be applied in printing a number of soft and tough structural materials such as actuators used in robotic systems.

“This is really beautiful work that demonstrates major advances in the utilization of tough hydrogels. This builds off earlier work using other polymer systems, with some of this earlier work done by Dr. Zhao, but the demonstration that one can achieve similar mechanical performance with a common biomedical polymer is a substantial advance,” said David Mooney, a professor of bioengineering at Harvard University who was not involved in this work.

It is also quite exciting that these new tough gels can be used for 3-D printing, as this is new for these gels, to my knowledge.

Mooney

The team members include mechanical engineering graduate student Shaoting Lin at MIT, graduate students Dalton Sycks and Hon Fai Chan; and Professors Gabriel Lopez, Farshid Gullak and Kam Leong at Duke.

The research was supported by the National Science Foundation, AOSpine Foundation, the Office of Naval Research and the National Institutes of Health.

References