Jun 11 2015

Researchers from the University of Twente have achieved 3D printing with metals, which has, until now, been possible only with plastic materials. A thin metal film was melted using a pulsed laser in order to create small metal droplets, which were microscopically stacked to 3D print copper and gold structures.

3D printing with metals offers great potential to expand manufacturing capabilities. As metals are robust and conduct both heat and electricity well, they are an ideal material for 3D printing entirely novel components, including connections between stacked chips or small cooling elements in smartphones.

Metals have a high melting point,making it difficult to deposit metal droplets in a controlled manner. For processing liquid metals, nozzles that are thermally robust are required. However, such nozzles are not easily available. Effective solutions for producing structures in the range of 100 nm to 10 μm are not available.

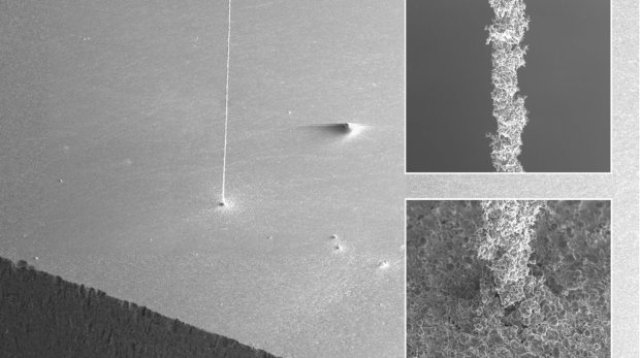

Researchers from the University of Twente and FOM have collaborated in this advancement for 3D metal printing. Using laser light, copper and gold were melted into small droplets in the micrometer range and deposited in a controlled way. The thin metal film was locally melted by a pulsed laser. The metal deformed and formed a flying drop, which was then positioned on a substrate in the desired location. Repetition of this process leads to formation of a 3D structure. Micropillars with a diameter of 5 μm and height of 2 mm required thousands of drops to be stacked upon one another. Selecting the specific location where the drop impacts can help create the desired shape.

Compared to earlier studies, the laser energy used was very high. This was required to boost the velocity of metal droplet impact. When the droplet impacts the surface, it becomes a disk-like shape and then solidifies. A robust 3D print requires a disk shape as it enables accurate stacking. Earlier attempts had involved low energies, which enabled printing of smaller droplets. However, these drops were spherical in shape, leading to a stacked structure with less stability.

An additional problem is faced when droplets land next to the desired location due to the high laser energy. This issue is to be addressed in future studies, which would enable printing using extremely thick fluids, gels, and metals.

This study has been published as a paper titled, “Towards 3D Printing of Pure Metals by Laser-Induced Forward Transfer,” in the journal Advanced Materials.