Goodfellow Ceramic and Glass Division offers Shapal™ Hi-M soft, a composite sintered body of AlN and BN that specifically addresses machining difficulties associated with the brittleness and hardness of traditional ceramics.

Shapal™ Hi-M soft allows for greater design freedom

Shapal™ Hi-M soft allows for greater design freedom

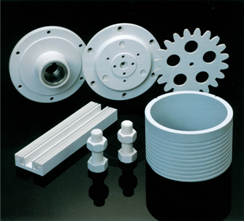

Shapal™ Hi-M soft can be machined into small or complex shapes and is suitable for a wide range of applications, thanks to its unique combination of properties:

-

Excellent machinability -- High-precision, close-tolerance components can be machined using a wide range of techniques including drilling, grinding, turning and milling

-

High thermal conductivity -- Approximately 4X that of alumina and at least 50X that of machinable glass ceramic

-

High mechanical strength -- It has a flexural strength of 300 MPa, comparable to alumina

Additional advantages include excellent electrical insulation, low thermal expansion, low dielectric loss, excellent high-temperature properties, and suitability for vacuum applications.

Typical applications of Shapal™ Hi-M soft include:

- Prototyping and small volume production

- Electrical components

- Heat sinks

- Vacuum components

- Jigs and fixtures

- Crucibles for vacuum applications

Shapal™ Hi-M soft is available from Goodfellow as rods and sheets or as finished components precision-machined to customer drawings.

For more information about Shapal™ Hi-M soft from Goodfellow, call 0800 151 3115 (UK freephone) or +44 1480 424 888, email [email protected] or visit www.goodfellow-ceramics.com.

Shapal-M is a trademark of Tokuyama Corp.

About Goodfellow Ceramic and Glass Division

Goodfellow Ceramic and Glass Division supplies a comprehensive range of ceramics and glasses to the research and industrial markets either as finished components to customer drawings or in an extensive range of semi-finished forms including sheets, rods and tubes for customers to machine their own components.

About Goodfellow

Goodfellow is a leading supplier of metals, polymers, ceramics and other materials to meet the needs of science and industry worldwide. The company specialises in supplying small quantities (a few grammes to a few kilos) of metals and materials for research, prototype development and specialised manufacturing applications. Standard products can be found online at the comprehensive Goodfellow Catalogue.