Researchers at Rice University have discovered that 3D structures of boron nitride, sometimes called "white graphene", could be used to control heat flow in small electronic devices.

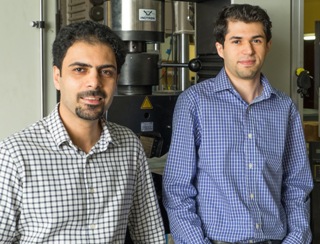

Rice University researchers Rouzbeh Shahsavari (left) and Navid Sakhavand have calculated the flow of heat across simulated structures of hexagonal boron nitride and boron nitride nanotubes. They report such structures may be suitable for controlling heat flow in electronics. (Credit: Jeff Fitlow/Rice University)

Rice University researchers Rouzbeh Shahsavari (left) and Navid Sakhavand have calculated the flow of heat across simulated structures of hexagonal boron nitride and boron nitride nanotubes. They report such structures may be suitable for controlling heat flow in electronics. (Credit: Jeff Fitlow/Rice University)

Rouzbeh Shahsavari, an assistant professor of materials science and nanoengineering, and Navid Sakhavand, a former graduate student at Rice University, have completed the first theoretical analysis of the application of 3D boron nitride as a tunable material to regulate heat flow in compact devices. The study has been published in ACS Applied Materials and Interfaces.

In its two-dimensional form, hexagonal boron nitride (h-BN), the material has a very similar structure to graphene. The major difference between the properties of the two materials is that h-BN is an electrical insulator, whereas perfect graphene monolayers are extremely good conductors.

However, similar to graphene, h-BN can conduct heat. This makes it of interest to designers of electronic devices, who are always looking for new materials which can help with heat management.

Shahsavari commented:

Typically in all electronics, it is highly desired to get heat out of the system as quickly and efficiently as possible. One of the drawbacks in electronics, especially when you have layered materials on a substrate, is that heat moves very quickly in one direction, along a conductive plane, but not so good from layer to layer. Multiple stacked graphene layers is a good example of this.

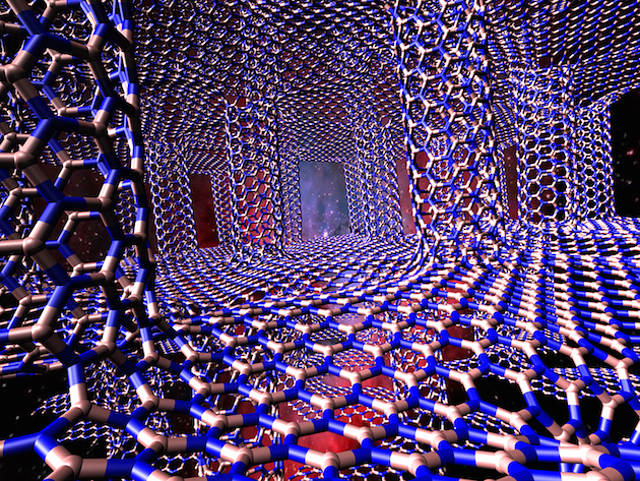

By creating 3D structures of h-BN layers connected by boron nitride nanotubes, the researchers showed that it is possible for the vibrations in the material to travel between planes as well as in-plane.

A 3-D structure of hexagonal boron nitride sheets and boron nitride nanotubes could be a tunable material to control heat in electronics, according to researchers at Rice University. Image credit: Shahsavari Group

Shahsavari and Sakhavand modelled a variety of structures with different nanotube dimensions to get a better understanding of the optimal properties. They observed that the junctions between the 2D sheets and the nanotubes reduced the heat flow, but that longer nanotubes enabled greater heat flow between layers, whilst shorter nanotubes tended to slow down heat conduction.

Graphene/carbon nanotube junctions have already been created in other research projects - if such junctions were made for boron nitride materials, Prof. Shahsavari is confident that they could be a highly promising solution:

Given the insulating properties of boron nitride, they can enable and complement the creation of 3-D, graphene-based nanoelectronics.

“This type of 3-D thermal-management system can open up opportunities for thermal switches, or thermal rectifiers, where the heat flowing in one direction can be different than the reverse direction.

This can be done by changing the shape of the material, or changing its mass – say one side is heavier than the other – to create a switch. The heat would always prefer to go one way, but in the reverse direction it would be slower.

The research team utilized the DAVinCI supercomputer supported by the National Science Foundation and administered by Rice University’s Ken Kennedy Institute for Information Technology, and also utilized computing resources supported by IBM, the National Institutes of Health, CISCO, Adaptive Computing and Qlogic. The study was funded by the Rice Department of Civil and Environmental Engineering and the National Science Foundation.

References and Further Reading:

"Dimensional Crossover of Thermal Transport in Hybrid Boron Nitride Nanostructures", Shahsavari and Sakhavand, Appl. Mater. Interfaces 2015