Electrically conducting fibers whose electrical conductivity increases by 200 times when stretched have been created by an international team of researchers based at The University of Texas at Dallas (UT Dallas). The fibres can be reversibly stretched to more than fourteen times their initial length.

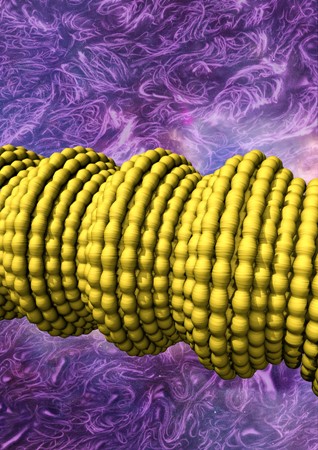

UT Dallas scientists have constructed novel fibers by wrapping sheets of tiny carbon nanotubes to form a sheath around a long rubber core. This illustration shows complex two-dimensional buckling, shown in yellow, of the carbon nanotube sheath/rubber-core fiber. The buckling results in a conductive fiber with super elasticity and novel electronic properties.

UT Dallas scientists have constructed novel fibers by wrapping sheets of tiny carbon nanotubes to form a sheath around a long rubber core. This illustration shows complex two-dimensional buckling, shown in yellow, of the carbon nanotube sheath/rubber-core fiber. The buckling results in a conductive fiber with super elasticity and novel electronic properties.

The researchers created the fibers by wrapping electically conductive sheets of carbon nanotubes around a long rubber core to form a sheath. While conventional fibers become increasingly electrically resistant when stretched due to a decrease in cross sectional area, these new fibers experience very little change in their resistance when stretched, according to Dr. Ray Baughman, director of the Alan G. MacDiarmid NanoTech Institute, UT Dallas, and senior author of this paper.

The rubber core is stretched lengthways as the sheets of carbon nanotubes are wrapped around it. These carbon nanofibres then buckle when the rubber is allowed to relax to its original length, ensuring that the fibre can be repeatedly stretched. “Think of the buckling that occurs when an accordion is compressed, which makes the inelastic material of the accordion stretchable,” said Baughman, the Robert A. Welch Distinguished Chair in Chemistry at UT Dallas.

"We make the inelastic carbon nanotube sheaths of our sheath-core fibers super stretchable by modulating large buckles with small buckles, so that the elongation of both buckle types can contribute to elasticity. These amazing fibers maintain the same electrical resistance, even when stretched by giant amounts, because electrons can travel over such a hierarchically buckled sheath as easily as they can traverse a straight sheath."

This buckling occurs both along the fiber's length and around its circumference. Dr Zunfeng Liu, lead author of the study, commented that:

Shrinking the fiber’s circumference during fiber stretch causes this second type of reversible hierarchical buckling around its circumference, even as the buckling in the fiber direction temporarily disappears. This novel combination of buckling in two dimensions avoids misalignment of nanotube and rubber core directions, enabling the electrical resistance of the sheath-core fiber to be insensitive to stretch.

These breakthrough fibers hold potential for applications such as super-stretchy charger cords for electronic devices, zero-failure pacemaker leads, wide-range strain sensors, morphing aircraft, exoskeletons and robots capable of achieving great reach, and interconnects for super-elastic electronic circuits.

The research team have created artificial muscles and strain sensors by adding a thin rubber overcoat and another carbon nanotube sheath to the sheath-core fibers. Here, the thin rubber layer acts as a dielectric and the buckled nanotube sheaths act as electrodes, thus forming a fiber capacitor. When stretched 950%, the capacitance of these fiber capacitors changed by 860%.

“No presently available material-based strain sensor can operate over nearly as large a strain range,” Liu said.

“Adding twist to these double-sheath fibers resulted in fast, electrically powered torsional — or rotating — artificial muscles that could be used to rotate mirrors in optical circuits or pump liquids in miniature devices used for chemical analysis”, said Dr. Carter Haines, a research associate in the NanoTech Institute and an author of the paper.

Nan Jiang, a research associate in the NanoTech Institute, showed that the conducting elastomers could be made with diameters ranging from 150 µm upwards by altering the size of the rubber core. “Individual small fibers also can be combined into large bundles and plied together like yarn or rope,” she said.

UT Dallas Nanotech CNT rubber fiber

“This technology could be well-suited for rapid commercialization,” said Dr. Raquel Ovalle-Robles MS’06 PhD’08, chief research and intellectual properties strategist at Lintec of America’s Nano-Science & Technology Center and an author on the paper.

“The rubber cores used for these sheath-core fibers are inexpensive and readily available,” she said. “The only exotic component is the carbon nanotube aerogel sheet used for the fiber sheath.”

In 2014, UT Dallas licensed a process developed by Baughman’s team to Lintec of America. Using the process, carbon nanotubes can be transformed into large-scale structures like sheets. Lintec launched its Nano-Science & Technology Center in Richardson, Texas, to produce carbon nanotube aerogel sheets for a wide range of applications.

The Air Force Office of Scientific Research, the Robert A. Welch Foundation, the U.S. Army, the National Institutes of Health, the National Science Foundation and the Office of Naval Research supported the work, which also received several funding sources Brazil and China.

Other authors based at UT Dallas’ NanoTech Institute include research scientists Dr. Márcio Lima and Dr. Shaoli Fang, and research associates Dr. Jiangtao Di and Dr. Xavier Lépro. Other contributors based at the UT Dallas Department of Mechanical Engineering are Dr. Hongbing Lu, professor; Dr. Dong Qian, associate professor; and Xuemin Wang, research assistant. Scientists from universities in Brazil, China, and Florida also contributed to this research work.

The study results have appeared in the July 24 issue of the Science journal.