A research team at UNSW Australia has developed a new model for fabricating metallic glass, an extremely strong alloy with high flexibility.

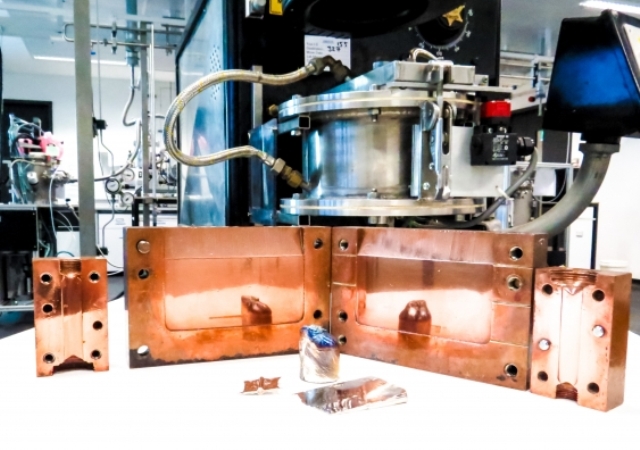

Metallic glass alloys developed by UNSW materials scientists. The team has developed a unique model of the atomic structure of metallic glass, which allows scientists to predict the metal combinations that will have glass-forming ability.

Metallic glass alloys developed by UNSW materials scientists. The team has developed a unique model of the atomic structure of metallic glass, which allows scientists to predict the metal combinations that will have glass-forming ability.

This work makes it possible to determine, for the first time, the right metal combinations to produce metallic glass, thereby facilitating the development of highly advanced materials with extreme strength and flexibility at a lower cost.

Metallic glasses exhibit glass-like or plastic characteristics, rather than metallic characteristics. Though they are metals, they can be effortlessly moulded or even blown like glass, and become as pliable as chewing gum when heated. Their average strength and hardness work out at three times that of ordinary metals, and thry rank amongst the strongest materials known.

“They have been described as the most significant development in materials science since the discovery of plastics more than 50 years ago,” says study author, UNSW’s Dr Kevin Laws.

Unlike most metals that have a crystalline structure in the solid state, with a regular, ordered structure of atoms, metallic glass alloys possess an irregular arrangement of atoms and an extremely disorderly structure.

“There are many types of metallic glass, with the most popular ones based on zirconium, palladium, magnesium, titanium or copper. But until now, discovering alloy compositions that form these materials has required a lengthy process of trial and error in the laboratory,” says Dr Laws.

Dr Laws and his team have explained their model in the journal 'Nature Communications'. This is the first model describing a metallic glass’ atomic structure. Using this model as an ‘instruction manual’, researchers are able to predict the right metal combinations for glass formation.

The team has used the new model over the past few years to successfully predict over 200 new metallic glass alloys based on metals including silver, magnesium, zinc, copper and titanium.

“With our new instruction manual we can start to create many new useful metallic glass-types and begin to understand the atomic fundamentals behind their exceptional properties. We will also be able to engineer these materials on an atomic scale so they have the specific properties we want,” says Dr Laws.

“Metallic glass alloys are expensive to manufacture and to date have only been used in niche products, such as ejector pins for iPhones, watch springs for expensive hand-wound watches, trial medical implants, and tennis racquets and golf clubs. They are also planned for use in the next Mars rover vehicle.

“But if they become easier and cheaper to make, they could be widely used in many applications including as exceptionally strong components in personal electronic devices, in space exploration vehicles, and as hydrogen storage materials in next generation batteries.”

Dr Daniel Miracle of the Air Force Research Laboratory, US Materials and Manufacturing Directorate, and Dr Laws and Professor Michael Ferry of the UNSW School of Materials Science and Engineering, are part of the UNSW research team.