A team of researchers from the Georgia Institute of Technology and the Singapore University of Technology and Design (SUTD) has proved that 3D printing technology could be used to create intricate self-folding structures.

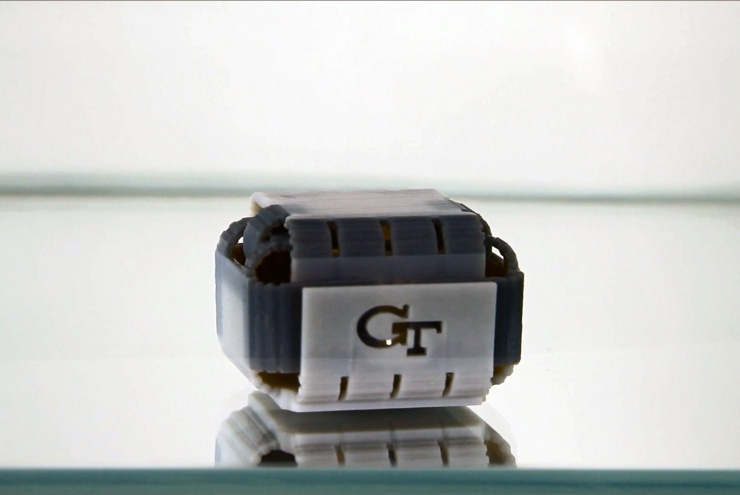

This image shows the folded box, which is intended to simulate a postal mailer. The folding is done in a tank of warm water to provide uniform heating to the materials. (Credit: Qi Laboratory)

This image shows the folded box, which is intended to simulate a postal mailer. The folding is done in a tank of warm water to provide uniform heating to the materials. (Credit: Qi Laboratory)

The researchers used components composed of smart shape-memory materials that show varied responses to heat.

The 4D technology demonstrated by the team could be applied to 3D structures capable of folding themselves in a sequence from components, which were rolled or flattened into a tube for the purpose of shipment.

The components could react to stimuli like moisture, temperature, or light such that they can be adapted for producing deployable medical devices, toys, space structures, robots, and several types of structures.

For the research, the team chose smart shape memory polymers (SMPs) which have the ability to remember one shape and transform to another prescribed shape during the application of uniform heat.

By printing many materials with varied dynamic mechanical properties in programmed patterns throughout a 3D object, it is possible to produce objects with shape changing ability in a controlled sequence over a period of time.

On heating these components, each SMP reacts at various rates and times to change its shape. By noting down the time taken for these changes, it is possible for 3D objects to be designed to self-assemble. The self-assembling structures were made from 3D printed patterns containing different quantities of SMPs.

A 3D printer was used for the purpose of patterning. The flat components caused by the patterning have diverse temporal reactions to the same stimuli. Former techniques needed varying levels of heat to be applied at pre-defined locations on the flat components in order to stimulate shape alterations.

Previous efforts to create sequential shape changing components involved placing multiple heaters at specific regions in a component and then controlling the on-and-off time of individual heaters. This earlier approach essentially requires controlling the heat applied throughout the component in both space and time and is complicated. We turned this approach around and used a spatially uniform temperature which is easier to apply and then exploited the ability of different materials to internally control their rate of shape change through their molecular design.

Jerry Qi, a professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech

The researchers illustrated their method using various examples. One example was a particular mechanism, which could be switched from a flat strip into a locked pattern with one end controllably bending and threading itself via a keyhole. Another example was of a flat sheet, which could self-fold into a 3D box consisting of interlocking flaps. Both these examples as well as others need accurate control of the self-folding steps of varied parts of the structure so as to prevent the components from colliding during the folding process.

We have exploited the ability to 3D print smart polymers and integrate as many as ten different materials precisely into a 3D structure. We are now extending this concept of digital SMPs to enable printing of SMPs with dynamic mechanical properties that vary continuously in 3D space.

Martin L. Dunn, a professor at Singapore University of Technology and Design

Using companion finite element simulations, the team predicted the responses of the 3D printed components. The components were produced from different ratios of two different SMPs available in the market. A simplified reduced-order model was built by the researchers to illustrate the physics behind the self-folding process rapidly and accurately.

An important aspect of self-folding is the management of self-collisions, where different portions of the folding structure contact and then block further folding. A metric is developed to predict collisions and is used together with the reduced-order model to design self-folding structures that lock themselves into stable desired configurations.

The team is hopeful that its novel technology would be applied in numerous applications such as unmanned air vehicles, which have the capacity to change shape and transform from a cruise mission to a dive mission. Another probable application would be 3D parts that can be rolled up into tubes or be folded flat for the purpose of easy transportation, but later returned to their intended 3D shape for use.

The research was published in the September 8th issue of the Scientific Reports journal by Nature Publishing.

Others involved in the study are co-author Yiqi Mao, and three other Georgia Tech collaborators: Kai Yu, Michael Isakov and Jiangtao Wu.

The U.S. Air Force Office of Scientific Research, the U.S. National Science Foundation and the Singapore National Research Foundation through the SUTD DManD Centre funded the research work.

References