NEI Corporation announced today that it has expanded its NANOMYTE® MENDTM line of top coats where a physical self-healing phenomenon leads to gap closing and crack sealing.

MEND is a technology platform of self-healing coatings applicable to a broad range of substrates such as metal, wood, and polymers – including those that require maintaining a clear glossy appearance. The NANOMYTE® MEND Line of products is suitable for use in solvent-based, water-borne, and UV-curable coating systems and various coating resins such as polyurethane, acrylic, and epoxy.

The innovative technology reduces life cycle costs by increasing the service life and reducing maintenance costs of the various substrates to which it is applied.

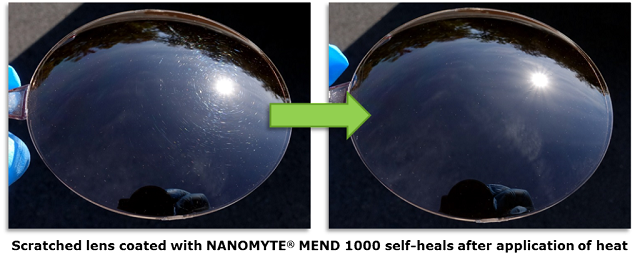

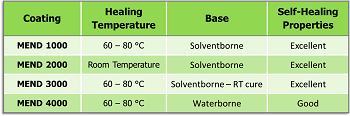

In response to the need for self-healing required in different environments, four MEND products have been introduced. MEND 1000 is based on US Patent 8,987,352, where a thermally induced physical self-healing phenomenon leads to gap closing and crack sealing. The self-healing coating involves a unique phase-separated morphology that facilitates the delivery of the self-healing agent to the damage site (such as a scratch or crack) thereby restoring the coating appearance & function.

The coating can be self-healed by the application of warm air for several seconds with a simple device, such as a household hair dryer. NANOMYTE® MEND coatings can be healed multiple times at the same defect location.

The properties of the coating – such as hardness, gloss, and refractive index – can be altered as needed for the specific application. The more recently developed, patent-pending MEND 2000 allows self-healing at near ambient temperature. MEND 3000 is a solvent-borne self-healing coating that can be cured at room temperature. MEND 4000, on the other hand, is a waterborne polyurethane-based, self-healing coating (US Patent 8,664,298).

The current series of MEND coatings are based on polyurethane, but the principle is applicable to other coating systems as well – including acrylics and epoxies, as well as UV-curable systems.

Self-healing principles can also be applied to surface treatments of metals. To this end, NEI has developed a series of pretreatments for different metals, where achemical self-healing mechanism imparts corrosion resistance. The US Patent and Trademark Office has issued a notice of allowance for NEI’s patent on anotherself-healing coating technology. The allowed claims describe a chemical conversion coating for protecting magnesium alloys from corrosion (NANOMYTE® PT-60).

PT-60 mimics the performance of chromate conversion coatings. The nanoscale structure of the magnesium surface allows ions to diffuse on demand to the damage site, forming a barrier that prevents further corrosion. Additionally, PT-60 has been engineered to act as a tie layer that bonds the overlying primer with the metal. Excellent field performance has been observed in select applications.

The NANOMYTE® MENDTM family of coatings complement NEI’s portfolio of Advanced Protective Coatings and Surface Treatments which provide tailored functionalities, such as hydrophobicity, superhydrophobicity, oleophobicity, superoleophobicity, self-healing, fog resistance, self-cleaning (or easy-to-clean), scratch resistance, anti-corrosion, and anti-icing.

In addition to imparting protective and aesthetic properties, NANOMYTE® coatings lead to gains in productivity and efficiency and therefore can be used in many applications that traditionally have not used paints or coatings. The coatings are versatile and can be applied on a variety of different substrates – including glass, plastic, fiber-composite, metal, and ceramic.

Contact us at [email protected] for additional information on our MEND coatings, including product specifications & a summary presentation.