At last week’s IEEE International Electron Devices Meeting 2015, world-leading nano-electronics research center imec presented three novel aluminum gallium nitride (AlGaN)/ gallium nitride (GaN) stacks featuring optimized low dispersion buffer designs.

Moreover, imec optimized the epitaxial p-GaN growth process on 200mm silicon wafers, achieving e-mode devices featuring beyond state-of-the-art high threshold voltage (Vt) and high drive current (Id).

To achieve a good, current-collapse-free device operation in AlGaN/GaN-on-Silicon (Si) devices, dispersion must be kept to a minimum. Trapped charges in the buffer between the GaN-based channel and the silicon substrate are known to be a critical factor in causing dispersion.

Imec compared the impact of different types of buffers on dispersion and optimized three types: a classic step-graded buffer, a buffer with low-temperature AlN interlayers, and a super lattice buffer. These three types of buffers were optimized for low dispersion, leakage and breakdown voltage over a wide temperature range and bias conditions.

Imec also optimized the epitaxial p-GaN growth process demonstrating improved electrical performance of p-GaN HEMTs, achieving a beyond state-of-the-art combination of high threshold voltage, low on-resistance and high drive current (Vt >2V, RON = 7 Ω.mm and Id >0.4 A/mm at 10 V). The P-GaN HEMT results outperformed their MISHEMT counterparts.

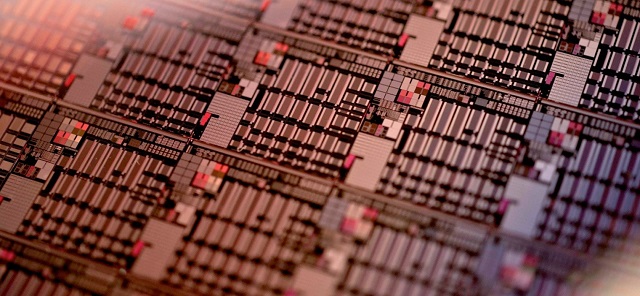

Imec’s GaN-on-Si R&D program aims at bringing this technology towards industrialization. Imec’s offering includes a complete 200 mm CMOS-compatible 200 V GaN process line that features excellent specs on e-mode devices. Imec’s program allows partners early access to next-generation devices and power electronics processes, equipment and technologies, and speed up innovation at shared costs.

Current R&D focuses on improving the performance and reliability of imec’s e-mode devices, while in parallel pushing the boundaries of the technology through innovation in substrate technology, higher levels of integration and exploration of novel device architectures.

“Imec’s presentations at the renowned IEDM meeting last week are a testament to the capabilities, sophistication, and maturity of our 200 mm GaN-on-Silicon platform,” stated Rudi Cartuyvels, executive vice president of smart systems and energy technology at imec.

“Building upon this success, we are now working with our GaN partners to implement and transfer specific device customizations. in parallel, we are exploring alternative substrate technologies to further push the boundaries of the GaN technology.”