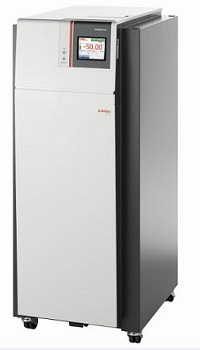

JULABO’s new PRESTO® models W50 and W50t provide a high dynamic temperature control system that can handle temperature ranges of -50°C to +250°C. Covering such an extremely broad temperature range means that the equipment is well-suited for demanding temperature applications such as reactors, mini-plants, pilot plants, material testing stands, micro-reactors, and material and component tests in the auto industry.

The new water-cooled PRESTO® models are available in two versions: the W50 and the W50T with increased heating capacity. Both models cover an extremely broad working temperature range, from -50 °C to +250 °C. The PRESTO® W50 provides a heating capacity of 6 kW, while the W50t provides double the heating capacity at 12 kW. Both instruments have a cooling capacity of up to 7.5 kW. They are ideally suited for compensating exothermic and endothermic reactions extremely quickly and have impressive, very rapid heat-up and cool-down times.

High-performance, maintenance free pumps deliver up to 3.2 bar or 76 l/min. Both models guarantee high flow rates at constant pressure and can interactively compensate changes in the viscosity of the tempering medium. The integrated 5.7” industrial color touchscreen of the new PRESTO® provides high functionality and intuitive user guidance.

Clear and well structured displays for values and graphics, all important information at a glance, detailed and easily understandable warning and help texts - these are just some of the advantages. Extensive interfaces allow flexible usage, such as control and regulation via USB interface, data logging via USB or SD Card, integration in process bus solutions (i.e., 2 of 3 Profibus), remote control via Ethernet networks or wireless control through JULABO’s WirelessTEMP application.

Competent advising, a collaborative search process for suitable solutions with the customer and many other customer services ensure that JULABO users find the ideal temperature control solution. JULABO supports its customers with installation and calibration, preparation of documentation for equipment qualification and application training so that the JULABO users can quickly and confidently master their equipment and use them for a long time.