Feb 10 2016

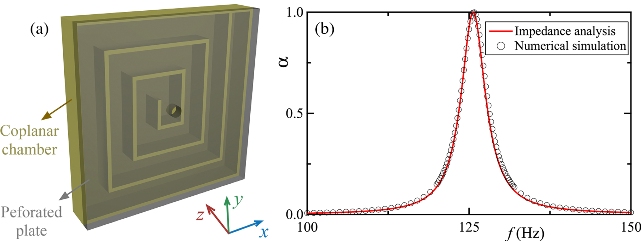

(Left) The metasurface composed of a perforated plate (transparent gray region) with a hole and a coiled coplanar air chamber (yellow region). (Right) The absorption coefficient, á, of the presented metasurface with a total absorption at 125.8Hz.

(Left) The metasurface composed of a perforated plate (transparent gray region) with a hole and a coiled coplanar air chamber (yellow region). (Right) The absorption coefficient, á, of the presented metasurface with a total absorption at 125.8Hz.

A design for a coiled acoustic metasurface, capable of realizing total acoustic absorption in ultralow frequencies, has been produced by researchers working at the French National Centre for Scientific Research, CNRS, and the University of Lorraine.

The main advantage is the deep-subwavelength thickness of our absorber, which means that we can deal with very low-frequencies – meaning very large wavelengths – with extremely reduced size structure.

Badreddine Assouar, a principal research scientist at CNRS in Nancy, France.

Assouar and Li, a post-doc in his group at the Institut Jean Lamour, affiliated with the CNRS and the University of Lorraine, have published their work in this week’s AIP Publishing’s Applied Physics Letters. Acoustic absorption systems absorb sound energy at a certain resonant frequency, and dissipate the energy into heat. Conventional acoustic absorbers comprise perforated plates that are placed facing hard objects so as to form air cavities. However, for operation at low frequencies, these absorbers must have a certain amount of thickness, which results in them becoming unsuitable for several applications.

To solve this challenge, Assouar’s team, whose previous work consisted of developing coiled channel systems, developed a new acoustic absorber, where sound waves go into an internal coiled air channel through a perforated center hole. This effect makes the sound waves to pass through the air channel, thus increasing their propagation length, and resulting in a high acoustic refractive index and low sound velocity. This gives the leverage to make the absorber relatively thin, even though the absorptive properties are similar to those of a thicker chamber.

A coiled chamber has acoustic reactance – analogous to electrical reactance, a property by which a circuit resists voltage or current change – that offsets the reactance of the hole, and enables achieving impedance matching. By this way, the total acoustic energy is transferred to the chamber, instead of being reflected, and is finally absorbed within the hole.

More applications of this type of metasurface may involve achieving phase profile and tunable amplitude for acoustic engineering, thus permitting modification of an acoustic wave’s propagation trajectory for specific applications including manipulation of particles having a vortex wavefront. Going forward, Assouar’s team will develop the sample fabrication processes using 3D printing and conduct performance analyses.