Feb 22 2016

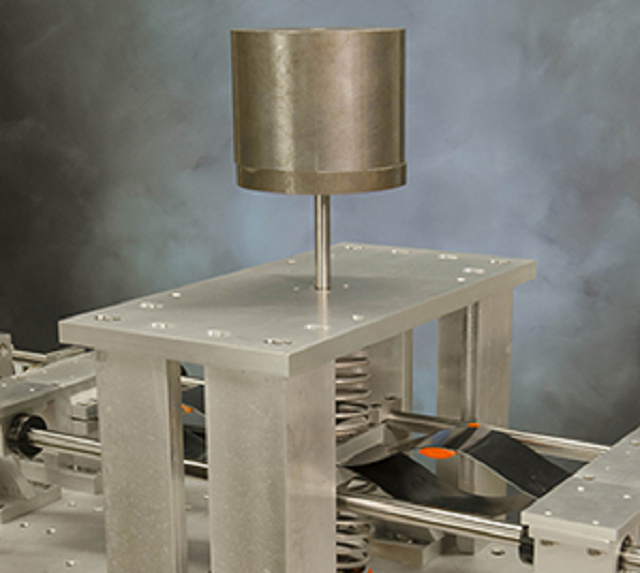

An active variable stiffness vibration isolator has been developed by researchers from HRL Laboratories’ Sensors and Materials Laboratory. This isolator is capable of millisecond actuation times and 100x stiffness changes, independent of the static load. In the words of Principal Investigator Christopher Churchill, “This performance surpasses existing mechanisms by at least 20 times in either speed or useful stiffness change.”

© 2016 HRL Laboratories.Photo by Dan Little.

© 2016 HRL Laboratories.Photo by Dan Little.

Churchill stated that the human body is built with a number of stiffness structures that carry out efficient nimble and load-bearing activity.

The most ubiquitous tunable stiffness structures are our own joints, which use antagonistic muscle contractions to vary joint stiffness continuously. For example, limbs will stiffen to lift a bowling ball, but soften to paint with the tip of a brush.

Christopher Churchill, Principle Investigator

The structures, present in human body, are not often replicated in engineered systems because of the cost, power and complexity involved in the entire process. Churchill explains that the conventional approach, which involves constructing a soft system followed by the addition of damping and force, is low-bandwidth and costly.

We developed a new paradigm, and instead built a stiff system and then softened it.

Christopher Churchill, Principle Investigator

The outcome is a cost-effective and high-bandwidth solution to prolonged challenges.

This newly developed isolator is widely used by manufactures of robotics, automobiles, watercraft, rotorcraft, and aircraft.

Advanced lightweight materials are increasingly finding their way into transportation platforms to achieve low mass and high stiffness. Utilizing adaptive negative stiffness to soften stiff systems on demand has the potential to solve shock and vibration problems that only get more difficult with these next-generation platforms.

Christopher Churchill, Principle Investigator

The February 2016 issue of Science Advances will feature the team’s findings, “Dynamically Variable Negative Stiffness Structures.”