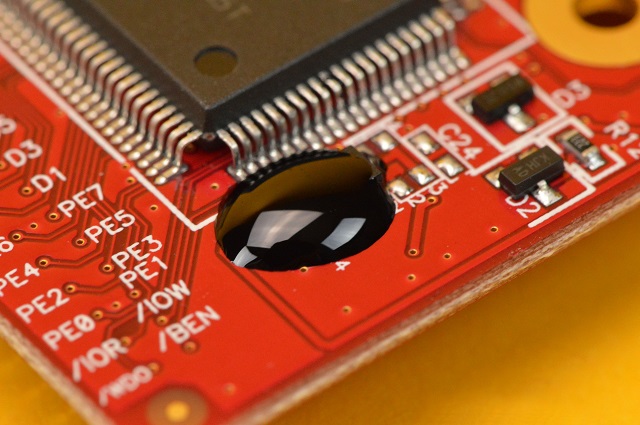

Formulated for many electronic applications, Master Bond Supreme 3HTND-2CCM is a multifunctional epoxy that is well suited for chip coating, glob top and die attach applications as well as for bonding, sealing and encapsulation.

Since it is a one part system, it does not require mixing and has an “unlimited” working life at room temperature. This epoxy passes NASA low outgassing tests which allow it to be used in vacuum, aerospace and clean room applications.

Supreme 3HTND-2CCM has a paste consistency that flows slightly while curing. It cures readily at elevated temperatures. The minimum curing schedule is 20-30 minutes at 250°F or 5-10 minutes at 300°F. This is a filled system with low shrinkage upon curing and sound dimensional stability.

It bonds well to a wide variety of substrates used in electronics including metals, composites, ceramics and many plastics. This high strength system delivers tensile lap shear, tensile and compressive strength of 1,800-2,000 psi, 6,000-7,500 psi and 15,000-17,000 psi, respectively.

This electrically insulative compound features a thermal conductivity of 10-11 BTU•in/ft2•hr•°F [1.44-1.59 W/(m·K)]. Supreme 3HTND-2CCM resists many chemicals, such as water, acids, bases, fuels and some solvents. Its inherent toughness allows it to withstand aggressive thermal cycling.

Supreme 3HTND-2CCM is serviceable over the wide temperature range of -100°F to +400°F. This epoxy has a black color and is available for use in syringe, pint, quart and gallon containers.

Master Bond High Temperature Resistant Adhesives

Supreme 3HTND-2CCM is a toughened, NASA low outgassing, high temperature resistant adhesive for demanding electrical applications. Read more about Master Bond’s heat resistant adhesives or contact Tech Support. Phone: +1-201-343-8983 Fax: +1-201-343-2132 Email: [email protected].