Feb 26 2016

Solar cells that are extremely lightweight, flexible, and thin can be placed on any kind of surface or material, which may include smartphones, helium balloons or even a sheet of paper.

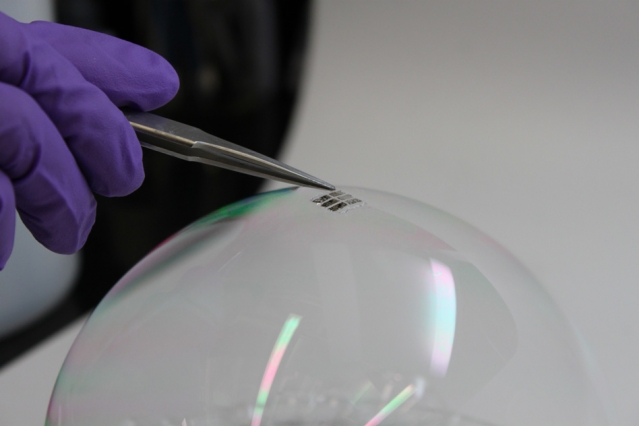

The MIT team has achieved the thinnest and lightest complete solar cells ever made, they say. To demonstrate just how thin and lightweight the cells are, the researchers draped a working cell on top of a soap bubble, without popping the bubble. Photo: Joel Jean and Anna Osherov

The MIT team has achieved the thinnest and lightest complete solar cells ever made, they say. To demonstrate just how thin and lightweight the cells are, the researchers draped a working cell on top of a soap bubble, without popping the bubble. Photo: Joel Jean and Anna Osherov

Recently MIT researchers have developed a new technique to produce thin and lightweight solar cells. Even though it may take years to commercialize these products, the laboratory proof-of-concept highlights a new approach to produce solar cells that could power the future generation of portable electronic devices. The new technique has been discussed in a paper by MIT professor Vladimir Bulović, doctoral student Joel Jean, and research scientist Annie Wang, in Organic Electronics.

Bulović, MIT’s associate dean for innovation and the Fariborz Maseeh (1990) Professor of Emerging Technology, points out that the key to this new process is to develop the solar cell, the substrate that provides support, and a protective overcoating to guard it from the environment. The substrate does not need to be cleaned, handled, or even detached from the vacuum during the process of fabrication, reducing exposure to dust and other contaminants that could degrade the performance of the cell.

The innovative step is the realization that you can grow the substrate at the same time as you grow the device.

Vladimir Bulović, Professor, MIT

The MIT team executed the experiment using parylene, a common flexible polymer, which served both as an overcoating and substrate. The researchers also used DBP, an organic material, as the chief light-absorbing layer. Parylene, a commercial plastic coating, was used to protect printed circuit boards and implanted biomedical devices from environmental damage. The whole process is carried out at room temperature in a vacuum chamber, without the need for any kind of solvent. This is different from the standard solar-cell manufacturing process, which needs strong chemicals and high temperatures. In this case, the solar cell and the substrate are grown using standard vapor deposition techniques.

The MIT team highlight that the specific materials were chosen only as examples, and that the main innovation is the in-line substrate manufacturing process. There is a possibility of using a wide range of materials for the encapsulation and substrate layers. Varied types of thin-film solar cell materials, including perovskites or quantum dots, could be exchanged for the organic layers utilized in the primary tests.

The team had already obtained the lightest and thinnest solar cells ever produced. To demonstrate the low weight and thinness of the solar cells, they arranged a working cell above a soap bubble without bursting the bubble. The scientists agreed that this solar cell may be too thin to be practical, but parylene films with thicknesses of up to 80 µm are capable of being deposited by commercial equipment, and retain the other benefits of in-line substrate formation.

A flexible parylene film, resembling the kitchen cling-wrap but measuring just one-tenth as thick, is initially deposited on a firm carrier material, which is glass in this particular case. Wang, who spent several years working with parylene, stated that the main challenge was how to efficiently separate the thin material from the glass.

The team used a flexible film frame to lift the whole parylene/solar cell/parylene stack from the carrier after completing the fabrication process. The final flexible, ultra-thin solar cells, including overcoating and substrate, measured just one-fiftieth of the thickness of a human hair and one-thousandth of the thickness of equivalent cells on glass substrates — roughly 2 µm thick — yet they are capable of transforming sunlight into electric current in a similar manner as their glass-based counterparts.

We put our carrier in a vacuum system, then we deposit everything else on top of it, and then peel the whole thing off.

Annie Wang, Research Scientist, MIT

Bulović states that like most new discoveries, it all sounds very easy once it is completed but actually a lot of effort is required to develop the methods to carry out the entire process.

While a glass carrier was used for the new solar cells, Jean says “it could be something else. You could use almost any material,” Given that the entire process happens under such benign conditions. For example, the solar cell and substrate could be directly deposited on paper or fabric.

The solar cell used in this experiment is not very efficient due to its lightweight feature, but its power-to-weight ratio seems to be one of the highest that has ever been achieved. This is vital for all applications where weight play a significant role, such as on high-altitude helium balloons or on a spacecraft used for research. However a typical silicon-based solar module, whose weight is overpowered by a glass cover, may produce around 15 W of power/kg of weight, the newly developed cells have already shown an output of 6 W/g — about 400 times higher.

It could be so light that you don’t even know it’s there, on your shirt or on your notebook. These cells could simply be an add-on to existing structures.

Vladimir Bulović, Professor, MIT

The team states that it will take time to develop this laboratory-scale work into a commercial product. While there exists some uncertainty about the commercial success of the new invention, this work could make room for new applications of solar power in the future. “We have a proof-of-concept that works,” Bulović says. The next question is, “How many miracles does it take to make it scalable? We think it’s a lot of hard work ahead, but likely no miracles needed.”

This demonstration by the MIT team is almost an order of magnitude thinner and lighter. It has tremendous implications for maximizing power-to-weight (important for aerospace applications, for example), and for the ability to simply laminate photovoltaic cells onto existing structures. This is very high quality work, [with a] creative concept, careful experimental set-up, very well written paper, and lots of good contextual information. The overall recipe is simple enough that I could see scale-up as possible.

Max Shtein, Associate Professor of Materials Science and Engineering, Chemical Engineering, and Applied Physics, University of Michigan

The National Science Foundation, and Eni S.p.A. through the Eni-MIT Solar Frontiers Center funded the study.