Apr 20 2016

In recent years, detector assemblies are becoming smaller and denser with a number of electronic components that have to be electrically connected to sense and read out signals. This has produced a greater challenge to design and manufacture these highly critical instrument devices.

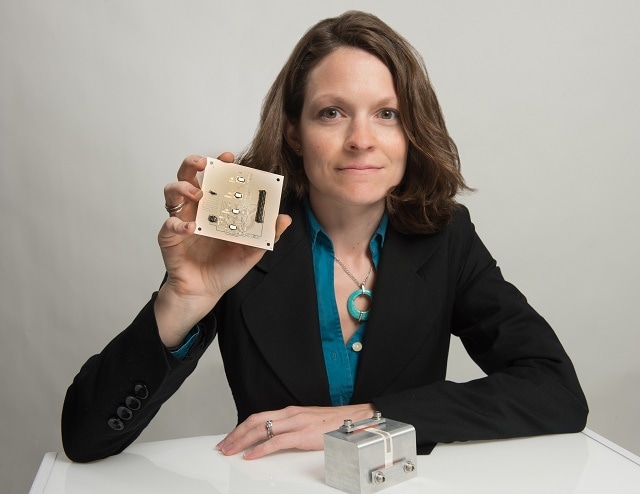

Goddard technologist Beth Paquette holds a 3-inch-by-3-inch ceramic board with four radiation-hardened digital-to-analog converter chips (in the middle of the board). She created the circuitry using a 3D printing technique using silver ink. Credits: NASA/W. Hrybyk

Goddard technologist Beth Paquette holds a 3-inch-by-3-inch ceramic board with four radiation-hardened digital-to-analog converter chips (in the middle of the board). She created the circuitry using a 3D printing technique using silver ink. Credits: NASA/W. Hrybyk

NASA technologists working at the Goddard Space Flight Center in Greenbelt, Maryland, have started to assess the use of a method known as aerosol jet printing or direct-write manufacturing to create novel detector assemblies that cannot be created using conventional assembly methods.

If we succeed aerosol jet technology could define a whole new way to create dense electronic board assemblies and potentially improve the performance and consistency of electronic assemblies.

Beth Paquette, Technologist, Goddard Space Flight Center

Additionally, she said that aerosol jet printing could enable a reduction in the time taken to manufacture circuit boards, from a month to a day or two.

Important Distinction

Similar to other 3D printing techniques, aerosol jet manufacturing constructs parts by depositing materials layer-by-layer based on a computer-aided design (CAD) drawing. However, jet aerosol printing has one vital difference.

Aerosol jet printing utilizes printer heads and a carrier gas to deposit a fine aerosol of metal particles, including gold, platinum, silver, or aluminum, onto a surface. Other 3D printers require the melting and fusing of plastic powder or some other material in accurate locations.

Aerosol jet printers can deposit polymers or other insulators and can also print carbon nanotubes, cylindrically-shaped carbon molecules possessing unique properties useful in electronics, nanotechnology, and optics.

It can print around bends, on spheres or on something flat, or on a flexible surface, which then can be flexed into the shape you want.

Beth Paquette, Technologist, Goddard Space Flight Center

These features make the technology highly suitable for detector assemblies, especially those that require varying shapes or are very tiny yet dense, due to the large number of miniature parts that have to be electrically wired or connected together on a circuit board. This is an unavoidable reality as instruments are becoming smaller and smaller.

We can make these wires microns in width. These lines are very small, down to 10 microns wide. These sizes aren’t possible using traditional circuit board manufacturing processes.

Beth Paquette, Technologist, Goddard Space Flight Center

Other Applications

However, the application of the method is not restricted to just detector electronics. NASA technologist Wes Powell, an electronics specialist at Goddard, predicts that there will be a time where instrument developers could apply aerosol jet technology to straight-away print wiring harnesses, antennas, and other hardware onto a spacecraft.

Paquette’s research involves NASA’s Marshall Space Flight Center, the University of Delaware, Georgia Tech, the National Institute of Standards and Technology, the University of Maryland’s Laboratory for Physical Sciences, and the University of Massachusetts-Lowell. In addition, a number of industry groups are involved, including the United Technologies Research Center, East Hartford, Connecticut; Raytheon, Waltham, Massachusetts; NanoDirect LLC, Baltimore, Maryland; and Optomec, Albuquerque, New Mexico.

The team has established that the technology has potential, and is now focused on testing the method’s robustness and repeatability especially for a spaceflight application.

Aerosol jet printing has the potential for many configurations, but the deposits have not yet been assessed under typical flight conditions. That’s what we’re doing here.

Beth Paquette, Technologist, Goddard Space Flight Center