May 25 2016

A team of researchers from the Max-Planck-Institut für Eisenforschung in Düsseldorf have created a novel metallic material, which possesses very high strength as well as ductility simultaneously.

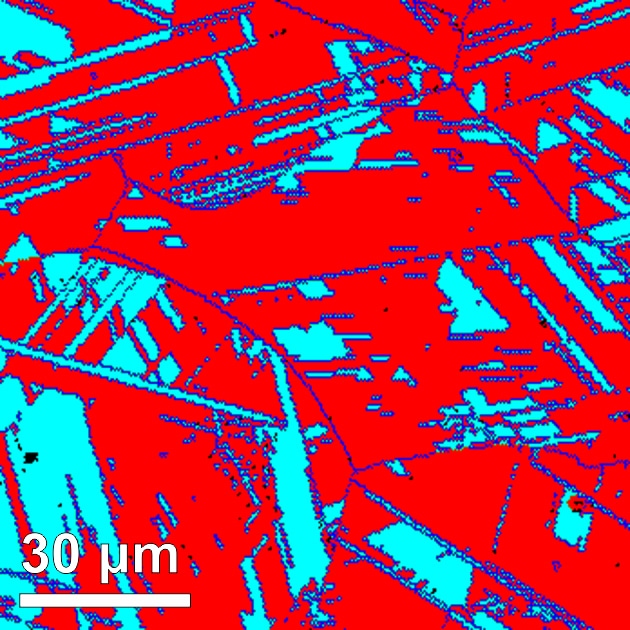

A strong alloy made of iron, manganese, cobalt and chrome becomes ductile because it can have two coexisting crystal structures, and one structure can transform into the other. The two crystal structures can be identified by the two different colours in this cross section of the material, which was produced with the aid of electron backscatter diffraction. (© Nature 2016/MPI f. Eisenforschung)

A strong alloy made of iron, manganese, cobalt and chrome becomes ductile because it can have two coexisting crystal structures, and one structure can transform into the other. The two crystal structures can be identified by the two different colours in this cross section of the material, which was produced with the aid of electron backscatter diffraction. (© Nature 2016/MPI f. Eisenforschung)

This has been a challenge for decades in the steel industry as when one property is enhanced the other suffers. Therefore, it is a breakthrough achievement by the Düsseldorf-based researchers, who are entering a totally new area in the field of metallic materials. It is likely that their work can be adapted for futuristic design of parts with thinner metallic sheets, which would reduce excess usage of resources.

It would be most suitable if steels and steel-related alloys could have both properties. This way they would not fragment, for instance when car bodies are involved in an accident or being processed in a mill. Simply put, they should be ductile, a term used by materials scientists. However, they also have to possess strength so that they would not break or warp when exposed to feeble forces.

The Düsseldorf-based researchers were led by Dierk Raabe, Director at the Max-Planck-Institut für Eisenforschung, and Cemal Cem Tasan, formerly head of a research group at this Institute and now professor at the MIT in the US, have successfully integrated both properties into a single material. So far, very ductile metallic materials did not possess sufficient strength and vice versa.

We pursued a new strategy in the development of this material, which generally opens up new possibilities for the design of metallic materials.

Dierk Raabe, Director, Max-Planck-Institut für Eisenforschung

The team started with a type of material that has been the subject of broad testing performed by materials scientists, but which was too fragile for use in several applications until recently: alloys in which metallurgists combine similar quantities of typically five or more different metals.

Atomic disorder enables high-strength alloys

Atoms of all the elements are spread along the positions in the crystal lattices found in these materials in a random order and the entropy is, to a specific extent, a measure for the disorder - these materials are called high-entropy alloys. Also, these kinds of materials are quite strong as the disorder of the various different atoms in a structure makes it hard for dislocations to travel.

Dislocations are deformations in the crystal lattice that travel via a crystal when a material becomes deformed. However, there is one downside to the high strength of the alloys with atomic disorder thus far. The issue is that the material tends to break under pressure as it is mostly brittle.

Steels have mostly iron, another key component, and minute quantities of other elements such as vanadium, carbon, or chrome, which are ductile in nature. They are not fragile; however, so far they have not possessed enough strength to enable, for instance, building of car bodies using thinner sheets.

In the steels’ crystals, the atoms are frequently in proper order. Steels become especially ductile although they can change from one structure to the next. This is due to the process consuming energy, which then prevents the chance for any damage in the material. In a car body or other steel parts, minute areas then swapped with the two varying atom arrangements.

The change in the crystal structure makes the material ductile

So far, it was precisely this coexistence of the diverse crystal structures that was unfavorable to the high-entropy alloys.

We have now turned this conception on its head, as recent studies have shown that this is not the important factor.

Zhiming Li, Max-Planck-Institut für Eisenforschung

Along with his colleagues, Li looked for a material that possessed strength as a high-entropy alloy and at the same time was quite ductile as steel, having two coexisting crystal structures.

He found an alloy composed of 50% iron, 30% manganese, 10% cobalt and 10% chrome.

With this alloy, we have shown that our concept works. If we further improve the microstructure and the composition, we can even further enhance the strength and ductility.

Dierk Raabe, Director, Max-Planck-Institut für Eisenforschung

This is currently the area that is being studied now. There is a possibility that they may at last solve the metal-processing sector’s issue of having to choose either strength or ductility in the materials.

The metallic materials created at the Düsseldorf-based materials forge could be processed quite as easily and economically as very ductile steel and soak up quite a lot of impact energy in an accident when integrated in a car body. Simultaneously, the material is strong enough, therefore cheaper and resource-saving metal sheets that do not break when a feeble force is applied.