Jul 11 2016

A paper published in Science revealed that a team of researchers have designed a method to reduce the use of platinum in chemical reactions that are commonly used in the automotive, green chemicals and clean energy industries has been reduced.

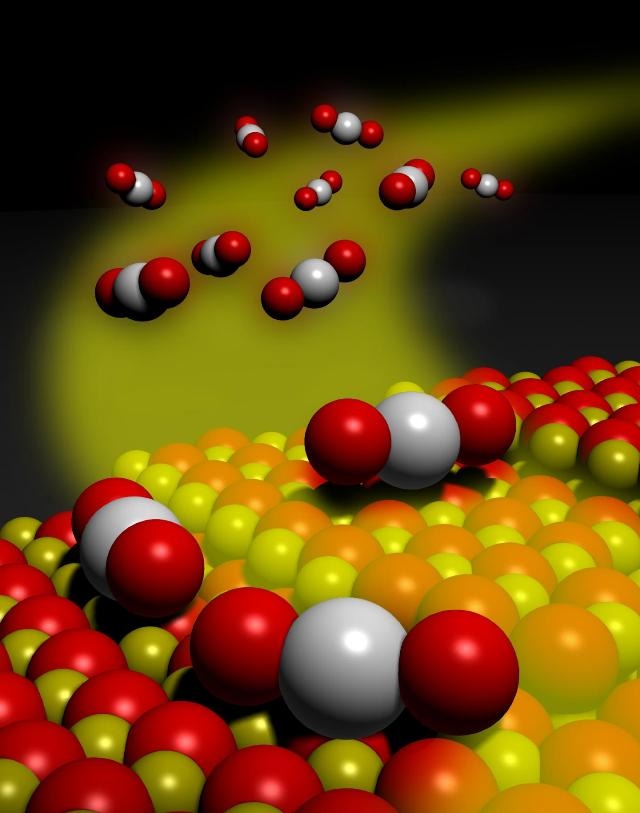

Mobile platinum oxide species trapped on a cerium oxide surface. The bonding of the platinum to surface oxygens creates isolated platinum atoms that are thermally stable and active for treatment of automotive exhaust pollutants. (Photo credit:

Washington State University)

Mobile platinum oxide species trapped on a cerium oxide surface. The bonding of the platinum to surface oxygens creates isolated platinum atoms that are thermally stable and active for treatment of automotive exhaust pollutants. (Photo credit:

Washington State University)

The research team, guided by the University of New Mexico in partnership with Washington State University the research team, developed a unique method to trap platinum atoms that enhanced the stability and efficiency of reactions.

Using less of rare, costly platinum

Various clean energy systems including fuel cells and catalytic converters use platinum as a catalyst. The valuable metal enables chemical reactions for various frequently used products and processes, including converting toxic carbon monoxide to carbon dioxide which is comparatively less harmful using catalytic converters.

Since platinum is expensive and rare, industries are keen to reduce the amount of platinum used and to design catalysts that have a higher efficiency in using individual platinum atoms in reactions.

However, the atoms tend to become mobile and join together as clumps at high temperatures. This decreases the performance and efficiency of the catalyst. Therefore, catalytic converters are routinely tested for effectiveness.

Precious metals are widely used in emission control, but there are always the issues of how to best utilize them and keep them stable. You want to use as little as possible to achieve your objectives, but it’s normally hard to keep the atoms highly dispersed under working conditions.

Professor Yong Wang, Washington State University

Nanoscale trap captures platinum atoms

The team formulated a technique to trap platinum atoms that keeps them stable and allows them to carry on their catalyzing function. The researchers used a general, low-cost manufacturing material, cerium oxide, to build a minuscule, nanoscale trap. They shaped the cerium oxide into nanometer-sized polyhedrons and rods, which resemble small pieces of rock candy, to trap the platinum atoms.

Due to their sufficiently high number of defects and large surface areas, the cerium oxide nanoshapes are capable of trapping the platinum atoms on their surfaces and keeping them from forming clumps, so that the platinum can carry on its function.

The atom-trapping technique should be broadly applicable for preparing single-atom catalysts. It is remarkable that simply combining the ceria with a platinum catalyst was sufficient to allow trapping of the atoms and retaining the performance of the catalyst. Even more surprising is that the process of trapping occurs by heating the catalyst to high temperatures – precisely the conditions used for accelerated aging of these catalysts.

Professor Abhaya Datye, University of New Mexico

Model for precious metal catalysts

There is no need for any rare precursors as the process of adding the cerium oxide to the catalyst is simple.

This work provides the guiding principles, so that industry can design catalysts to better utilize precious metals and keep them much more stable.

Professor Yong Wang, Washington State University

The National Science Foundation (GOALI grant CBET-1438765), the U.S. Department of Energy’s Office of Basic Energy Sciences and General Motors Co funded the research.

This research is in line with WSU’s Grand Challenges, a collection of research initiatives focused on large societal challenges. It is mainly applicable to the challenge of sustainable resources and its subject of energy.